Founded in 1990, Sharpe Products is an ISO 9001:2015 certified company specializing in industrial and commercial pipe and tube bending, laser cutting, end-forming or other custom fabrication services. In addition, we offer a robust line of architectural handrail fittings and accessories such as brackets, connectors, disks, end-caps, flanges, newel caps and spheres.

Founded in 1959, Tube Bending Technology has its roots in the Apollo space program. With such a legacy, we take quality, performance and customer satisfaction very seriously. Our custom tubing services include tube bending and coiling, end finishing, processing, machining, welding/brazing, helium leak detection and more. At TBI, we live and breathe quality. To show our commitment, we are ISO...

At KMK Metal Fabricators, Inc., we pride ourselves on being industry leaders in tube fabrication, offering a comprehensive range of services tailored to meet the diverse needs of our clients. With years of experience, a commitment to excellence, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our core focus lies in providing...

SCR Precision Tube offers the best customer service in the industry, specializing in prototyping & design of tube, hose & fittings assemblies. Our CNC facility has full tube bending, cutting & swagging capabilities with elbows & straight tubing in steel, aluminum, copper & titanium. Email for a quote!

At TBC Metalworks, we take pride in our expertise in tube fabrication, offering tailored solutions to meet the diverse needs of our clients across various industries. With years of experience, a commitment to quality, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our primary focus is on providing a comprehensive range of tube...

More Tube Swaging Manufacturers

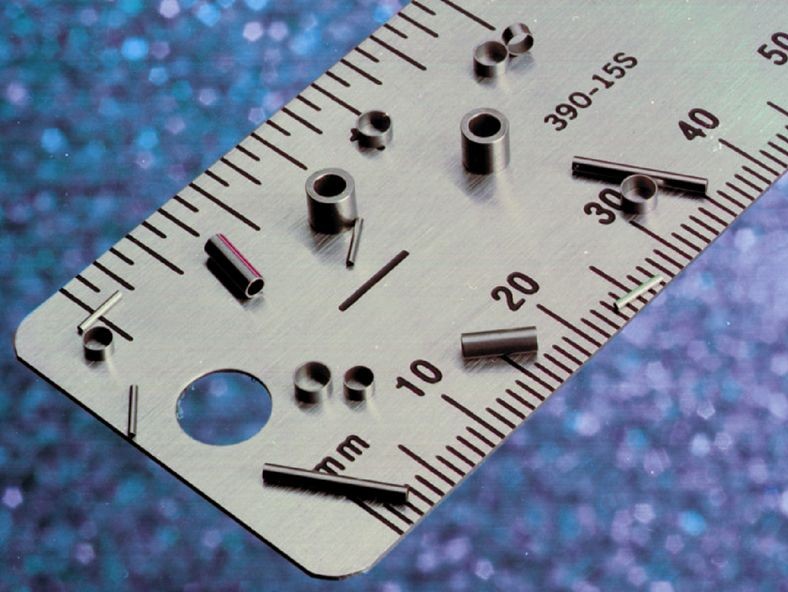

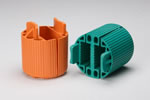

Unlike forging which uses heat to mold the tubing, tube swaging is cold-worked under high pressure, and is basically a deformation of the tube or pipe to attach to another tube or pipe and form its final shape. A mechanical or hydraulic tool compresses and reshapes the fitting, creating a permanent join between the previously unattached parts.

Tube swaging is one of the many specialized services of tube fabricating, and should be done by qualified personnel. Many industries require the use of pipes and tubing, and thus require the ability to connect tubes to create a flow system. Swaging and flaring tools easily merge wires and pipes, bending and fitting individual pieces together to create sealed joins.

Radial hammering is a process used to compress the pipes, adjusting the shape and diameter of the tube under repeated pressure. Tube diameters can be reduced in order to be fed through the die block and prepared for attachment. Tube flaring, a similar process to swaging, creates a funnel shape at the end of a tube that matches the fitting or component it is to be attached to.

Wires and pipes are easily joined together through the process of swaging as it bends and fits individual sections together to create a cohesive system. With the complicated system of tubes in many appliances and machines, it is important the ends of the tubes and piping fit together in a tight seal. Leaks can be hazardous and cause damage to the unit, and to the people using it.

Swaging is accomplished by using a tube die to compress one tube in order to reduce its diameter, it is then connected to another pipe or fitting and compressive force is applied to form a join. The inner diameter of the tube can be a different shape as a result of the compression. Swaging is the method commonly chosen for fabricating precious metals as there is no material lost during the process; rather it is simply a compression and reshaping of the existing material.

Tube swaging and tube end forming are used with various material alloys such as stainless steel, aluminum, steel, titanium, copper or brass. Common industries that utilize the process of tube swaging include aerospace, medical, automotive and commercial, and in a variety of commonly used machines and appliances.

Broaching

Broaching CNC Machining

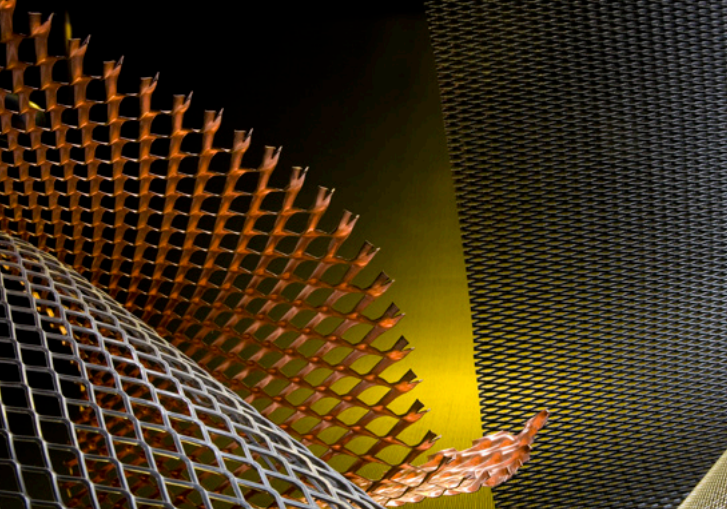

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

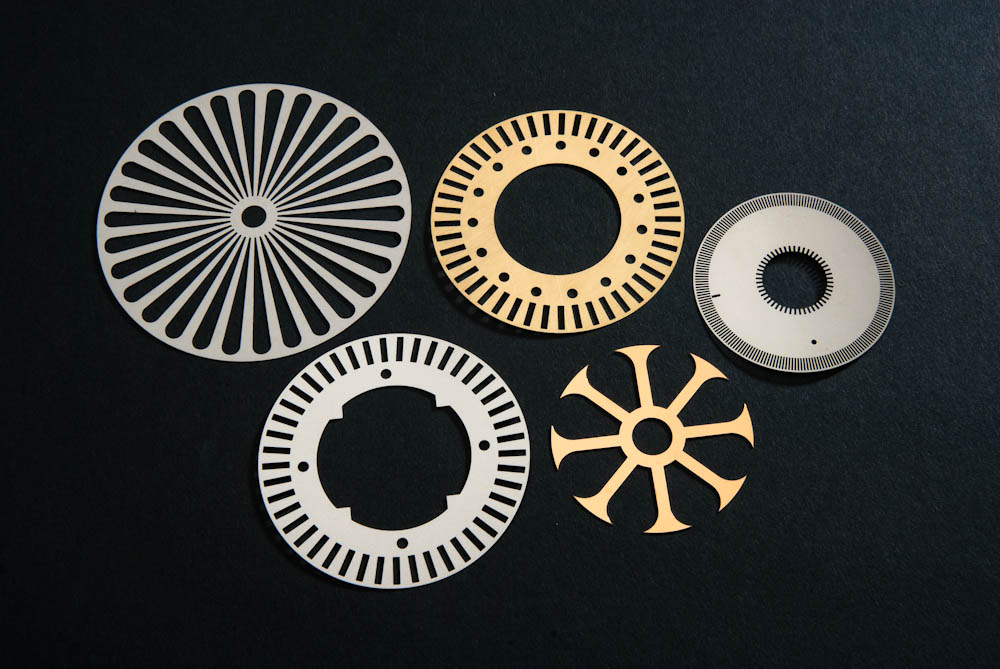

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

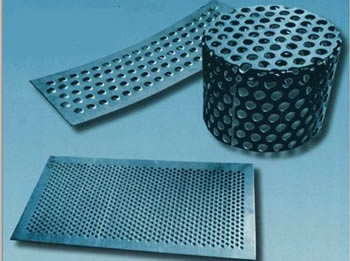

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

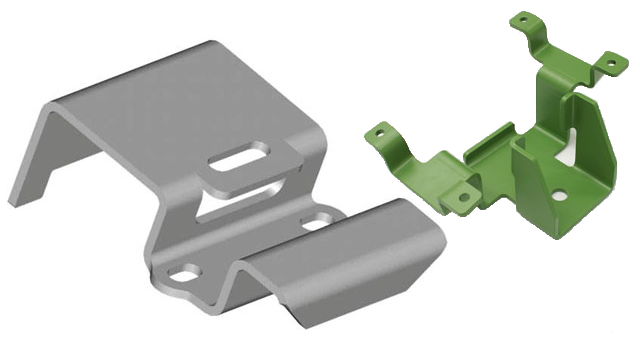

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services