Founded in 1990, Sharpe Products is an ISO 9001:2015 certified company specializing in industrial and commercial pipe and tube bending, laser cutting, end-forming or other custom fabrication services. In addition, we offer a robust line of architectural handrail fittings and accessories such as brackets, connectors, disks, end-caps, flanges, newel caps and spheres.

At Precision Bending Technology, Inc., we take immense pride in our expertise in tube fabricating. Established with a passion for precision and a commitment to excellence, we, as a team, have seamlessly blended innovation with experience to become a leading force in the industry.

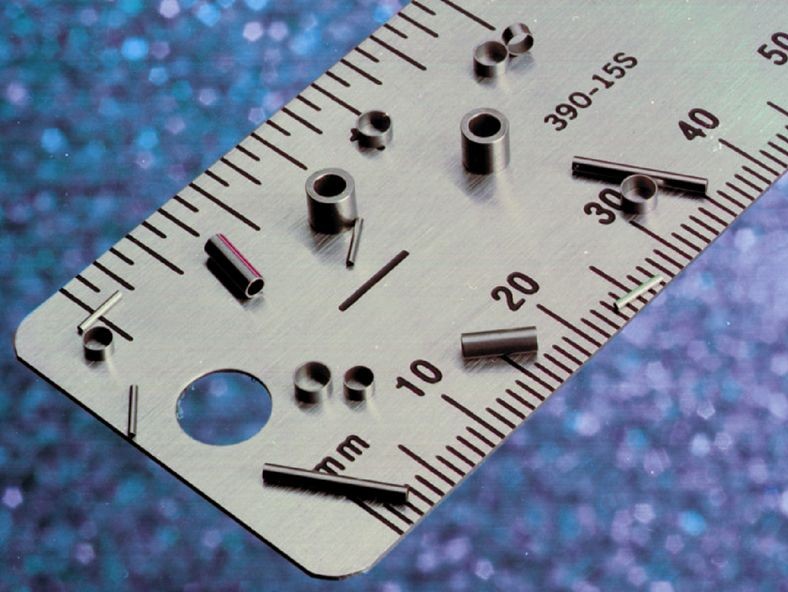

Here at Zeman Manufacturing Company we offer a number of services and products including: tube bending, tube end forming, tube assembly, tube cutting, hypodermic tube fabrication, tube coiling, tube swaging, lubricating oil cups, metal tube spacers and custom miniature headers. If you have any specialized requests then give one of our representatives a call today! Please visit our website if you...

Our tube bending capabilities range from 1/32” to 3/8” thickness & in shapes such as round, square, rectangle, oval, and specially designed. At Crest Bending we can do tube swaging (end forming) to reduce, flare, expand, bead, notch and slot. Our bending department possesses a broad range of capabilities including pipe bending, pipe fabrication, tube cutting, tube fabrication, tube flaring &...

JBK Manufacturing is a supplier of precision CNC machined parts and fabrications. Since our founding in 1981, our customer base has expanded from an aerospace contract to include a host of commercial and industrial markets, defense, energy, oil, and paper industries.

Send Requests For Quote to Multiple Tube End Forming Suppliers Near You

Provide your project details, and we'll connect you to 5-20 qualified Tube End Forming companies in your region. 100% free.

Get InformationManually Sourcing U.S./Canadian Manufacturers for 20+ Years

More Tube End Forming Manufacturers

Tube end forming companies use end forming machines that suit the type of forming method based on the application.

End-forming is a technique used to alter a tube's geometry, usually at or close to the end of the material. The procedure has been used for many years, but manufacturers have switched to custom machine-forming since it is more economical. Using a procedure called tube end formation, hollow tubes can have their ends shaped. Tube end shaping can produce a variety of end shapes, including expanded ends, curled ends, flanged ends, beaded ends, and flared ends.

For the application, type of material, and machine being used, many various shapes on tube ends can be obtained with good end forming equipment. Tooling standards are determined by factors like hardness, tube end preparation, tooling coatings, and material type. Based on the materials and intended expansion, different types of lubricants are utilized in the process. In general, end-forming is a desirable and effective method for creating tubes. Parts can be manufactured for different product applications in small and large volumes.

Types Of Tube End Forming

There are many different varieties of tube end shaping. Some of the main types used in different sectors include:

Beading

In many different sectors, beading is utilized as a connecting or sealing point between two matching parts. Beading is mostly used in the production of automotive parts since it has a tighter tolerance and helps to stop fluid leaks. Beads come in a wide range of forms, sizes, and materials. Inverted beads have a rotating end and are utilized as rollers for conveyor systems and as a place to seat an O-ring on the tube's outer diameter.

Knurling

Knurling is an end-shaping technique that gives the tube's surface roughness. This process is used to increase the surface area of a tube's outside diameter so that a mating component, usually a hose or other flexible media for fluid transfer, will have more grip area. Low-pressure fuel lines and coolant are examples of real-world uses. When the formed item fits on a hose, knurling is a technique that is utilized in conjunction with a bead. Some end-forming techniques allow for the simultaneous formation of the bead and knurl. Rotary end shaping is the technique of choice for knurling tube ends.

Reductions

Tube reducing is the technique of lowering a portion of a tube's outer diameter so that it can be utilized in a full assembly with another matching component. Reduction is one of the most widely used applications worldwide. Many commonplace products, including automobiles, trucks, airplanes, water lines, and more, use tube reductions. The reduction's size will change depending on how it is used. While some reductions are significantly lowered for tie rods or other uses, others are just slip-fit to be used in exhaust assemblies.

The optimal tube end forming method depends on the application at hand and factors such as wall thickness and tube diameter. For most thick wall applications, ram end shaping is best. For tubes with average walls that don't require a significant decrease, segmented end shaping is the best option.

Expansions

The process of expanding a length of tube beyond its nominal diameter is known as "tube expanding." Expansions, like their tube reduction cousin, are frequently utilized in a variety of applications. The optimal tube end forming method depends on the application and the tube's wall thickness and diameter. The optimum procedure is progressive ram end shaping for expansions bigger than one inch. When the expansion range is less than 1 inch in diameter and the wall thickness is less than 120, segmented end forming is the best option.

Coping

Cutting one section of tube to fit against another is known as "tube coping." Coping is a technique used to prepare the ends of tubes before they are joined to form a final assembly. Roll cages, furniture frames, and other items are examples of real-world usage. Ram-end shaping is a useful technique for dealing with tubes in high-volume manufacturing.

Application Of Tube End Forming

Another item may be assembled onto the end of a tubular element using a tubular end formation.

- Compressor air tubes

- Pneumatic lines

- Fluid transfer heat exchanges

- A multitude of electronic parts

- Oil filters

- Hydraulic lines

- Medical devices

Advantages Of Tube End Forming

Some advantages to end forming tubes include:

- Enhanced tube strength

- Increased sealing capabilities

- Connectivity improvements

Choosing the Right Tube End Forming Company

To make sure you have the most productive outcome when selecting a tube end forming company, it is important to compare at least 4 to 5 companies using our tube end forming directory. Each tube end forming company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each tube end forming company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple tube end forming companies with the same quote.

Broaching

Broaching CNC Machining

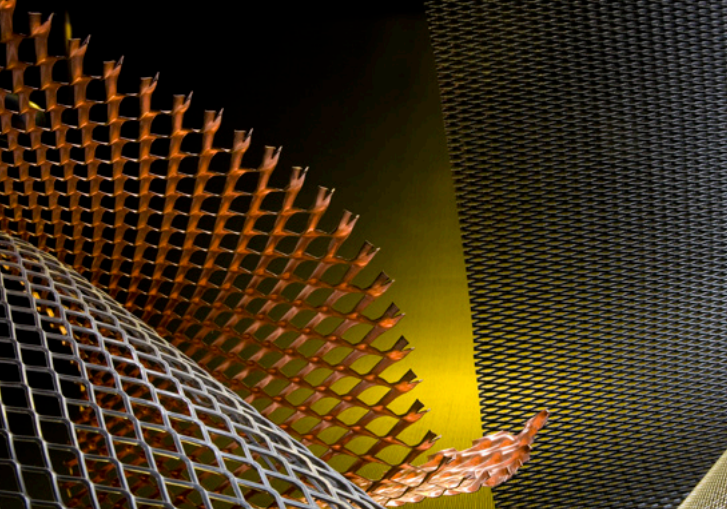

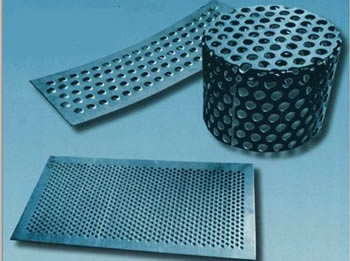

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

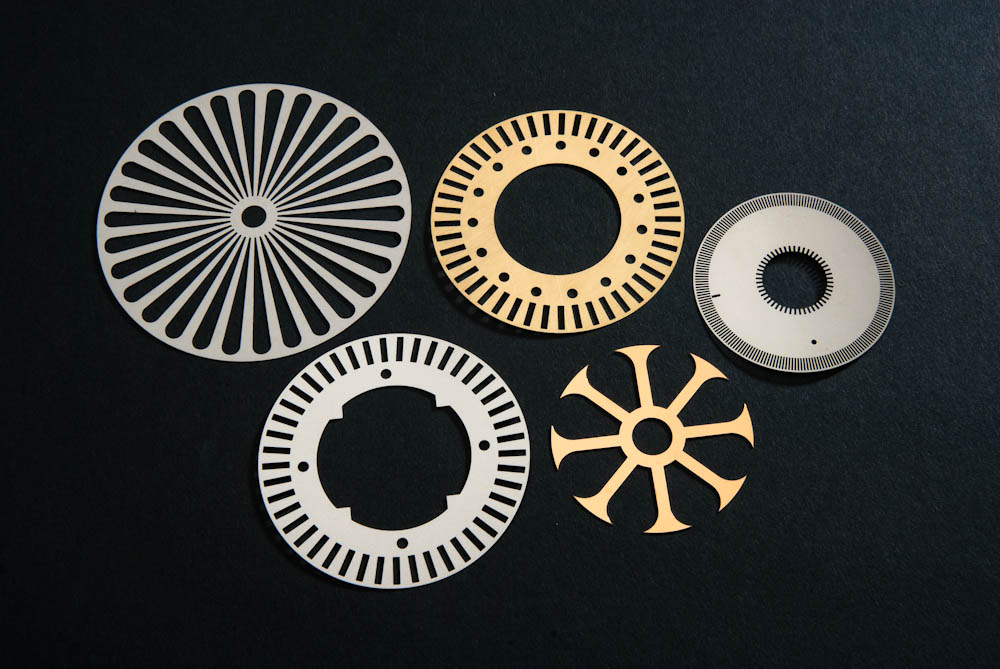

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

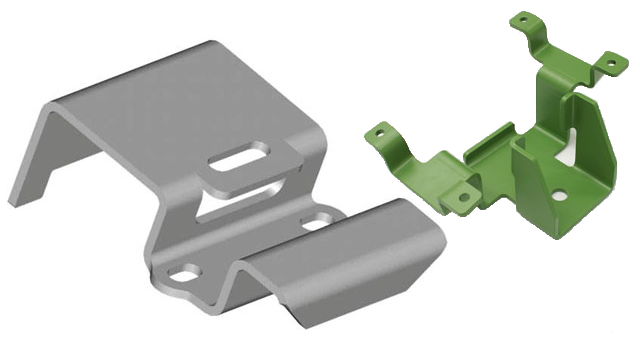

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

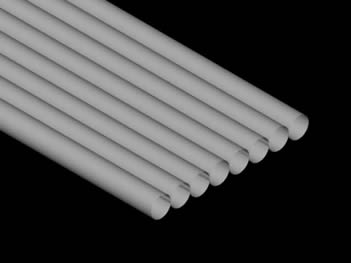

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

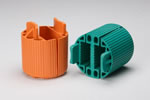

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services