Founded in 1990, Sharpe Products is an ISO 9001:2015 certified company specializing in industrial and commercial pipe and tube bending, laser cutting, end-forming or other custom fabrication services. In addition, we offer a robust line of architectural handrail fittings and accessories such as brackets, connectors, disks, end-caps, flanges, newel caps and spheres.

Founded in 1959, Tube Bending Technology has its roots in the Apollo space program. With such a legacy, we take quality, performance and customer satisfaction very seriously. Our custom tubing services include tube bending and coiling, end finishing, processing, machining, welding/brazing, helium leak detection and more. At TBI, we live and breathe quality. To show our commitment, we are ISO...

At KMK Metal Fabricators, Inc., we pride ourselves on being industry leaders in tube fabrication, offering a comprehensive range of services tailored to meet the diverse needs of our clients. With years of experience, a commitment to excellence, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our core focus lies in providing...

SCR Precision Tube offers the best customer service in the industry, specializing in prototyping & design of tube, hose & fittings assemblies. Our CNC facility has full tube bending, cutting & swagging capabilities with elbows & straight tubing in steel, aluminum, copper & titanium. Email for a quote!

At TBC Metalworks, we take pride in our expertise in tube fabrication, offering tailored solutions to meet the diverse needs of our clients across various industries. With years of experience, a commitment to quality, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our primary focus is on providing a comprehensive range of tube...

More Tube Bending Manufacturers

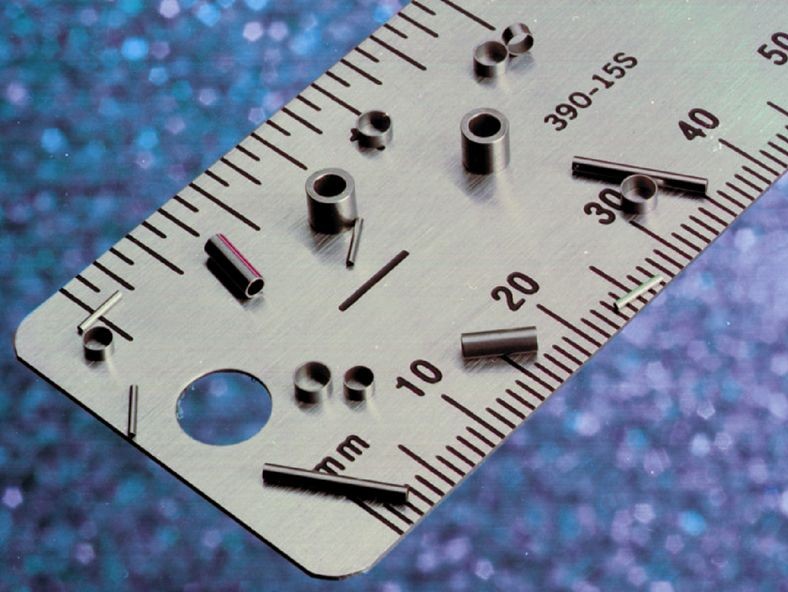

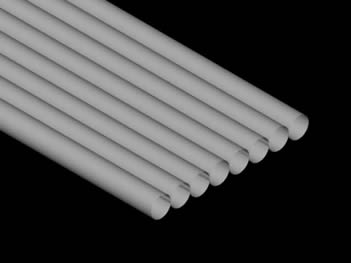

Tube bending companies, which manufacture and supply the equipment for tube bending, consider mostly the type of material to be bent as well as the inside and outside diameters of the tube.

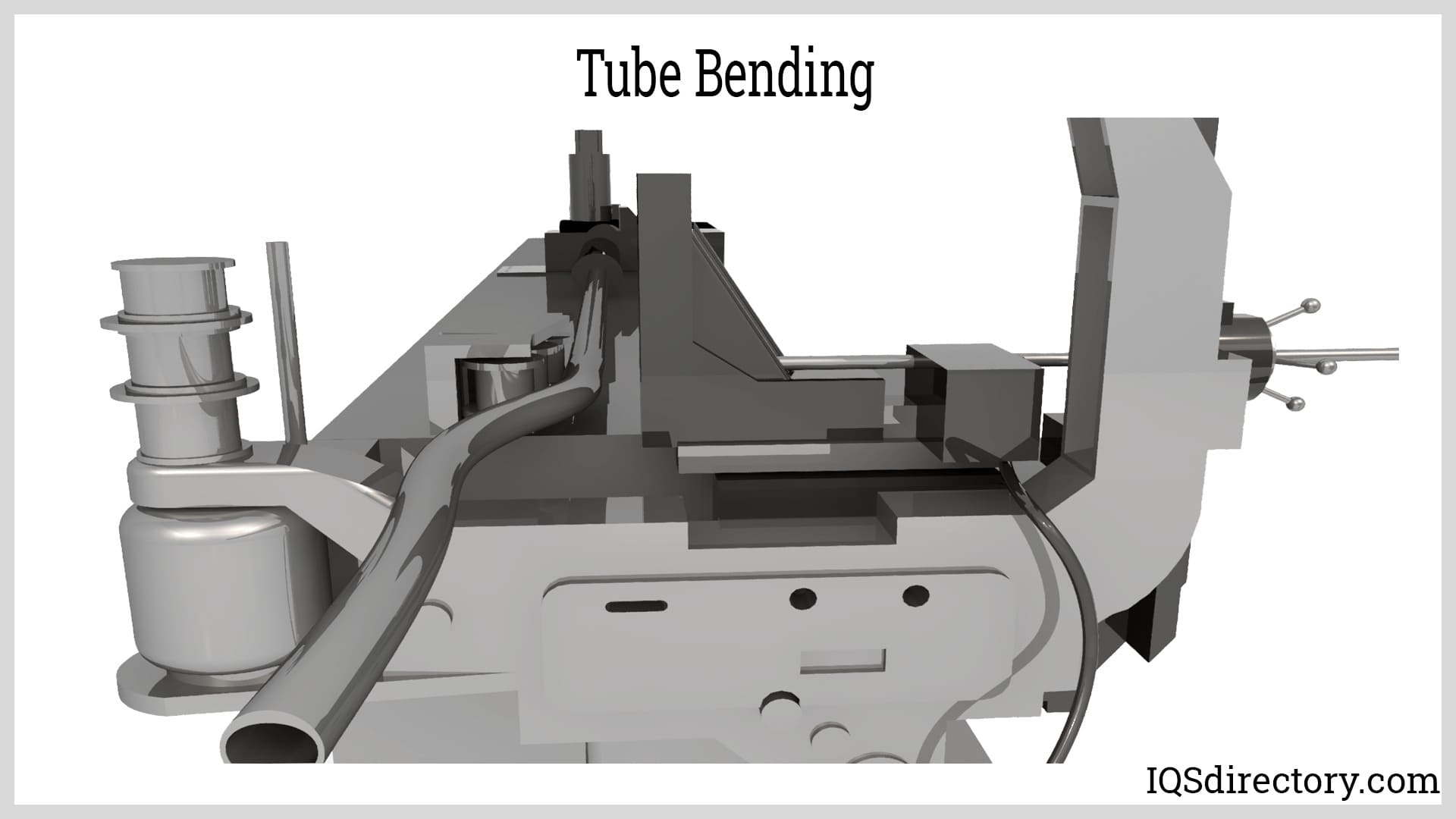

Any metal forming technique used to permanently shape pipes or tubing is known as tube bending. Tube bending techniques can be either form-bound or freeform, and they can be either heat-supported or cold-formed.

The work item is bent using form-bound bending techniques such as "press bending" or "rotary draw bending." A bending machine can be used to bend straight tube material into a range of single or multiple bends and to give it the appropriate shape. Using these procedures, complicated shapes can be created from many types of ductile metal tubing. The workpiece is kinematically shaped by freeform bending techniques like three-roll-push bending, so the bending contour is independent of the tool geometry.

Types Of Bending Processes

Most tubes are bent one of four ways: rotary draw bending, roll bending, ram-type bending, and compression bending.

Rotary Draw Bending

In rotary draw bending, a cold bending technique, the part is fastened to a spinning bend die and dragged around the bend die. A pressure die presses the tailing tangent against the bend die as the bend die rotates to create the appropriate geometry. To prevent cross-sectional deformation during the bending operation, a mandrel is frequently inserted inside the member. Additionally, bends may be produced using specialized draw-bending machinery, in which deformations are managed by tensioning along the member axis.

When extremely high precision is required, rotary draw bending is frequently used to create small radius bends in smaller-sized round, square, and rectangular HSS pieces. This method is best suited for projects needing numerous similar bends because specific tooling is needed for each member's size, shape, and bend radius. In the machine and component sectors, as well as for piping, this bending technique is primarily employed.

Roll Bending

In construction, roll bending is frequently used for big workpieces. Three rolls are typically arranged in a pyramid shape and can be oriented either vertically or horizontally, depending on the size of the workpiece. Rolls are moved to create precise radii, which are typically very big. The mechanism decides which rollers move in which directions. Roll bending is typically used to create spirals or to give a metal sheet a big, smooth radius. A different kind of machine is a pinch-style, two-roll roll bender. In this system, the tube feeds between an upper and lower roll, and two movable guides on either side of it move to provide the required bend angle.

Compression Bending

In compression bending, the workpiece is bent around a stationary bend die using a roller or compression die (also known as a follow block). Just behind the rear tangent point, the system compresses the tube against the fixed bend die and clamps the workpiece from behind. The tube is "compressed" against the central bend die by the roller in an effective manner.

The most typical application of this technique is for symmetrical workpieces, or those with identical bends on either side, which are frequently bent in a single setup using a machine with two bending heads. When tubes are bent to a CLR that is at least three times the tube OD, this technique works well. This process is used to make the majority of household and commercial products.

Ram-type Bending

One of the earliest and most basic techniques for tube bending involves pushing a tube against rollers or pivot blocks with the use of a hydraulically powered ram. Ram-type bending can achieve three to four times the original diameter of the workpiece by driving a hydraulic ram against rollers or pivot blocks. This technique is widely used in applications involving square tubing, and many people intentionally compress and slightly distort the inside bend radius when designing the ram tool for those applications. Although it is the least expensive option for bending tubes or pipes, it is not as precise as some of the other approaches.

Applications Of Tube Bending

- Furniture components

- Agricultural and transportation equipment

- Structural steel bending and rolling

- Ductwork for clean rooms and processing plants

- Bent metal for playground equipment

- Bent metal for fitness equipment

- Construction and architectural accents

- HVAC and refrigeration pipes, tubes and components

- Pneumatic conveying systems

- Petrochemical and offshore equipment

- Tanks and steel vessel supports

- Streetlamps and signage

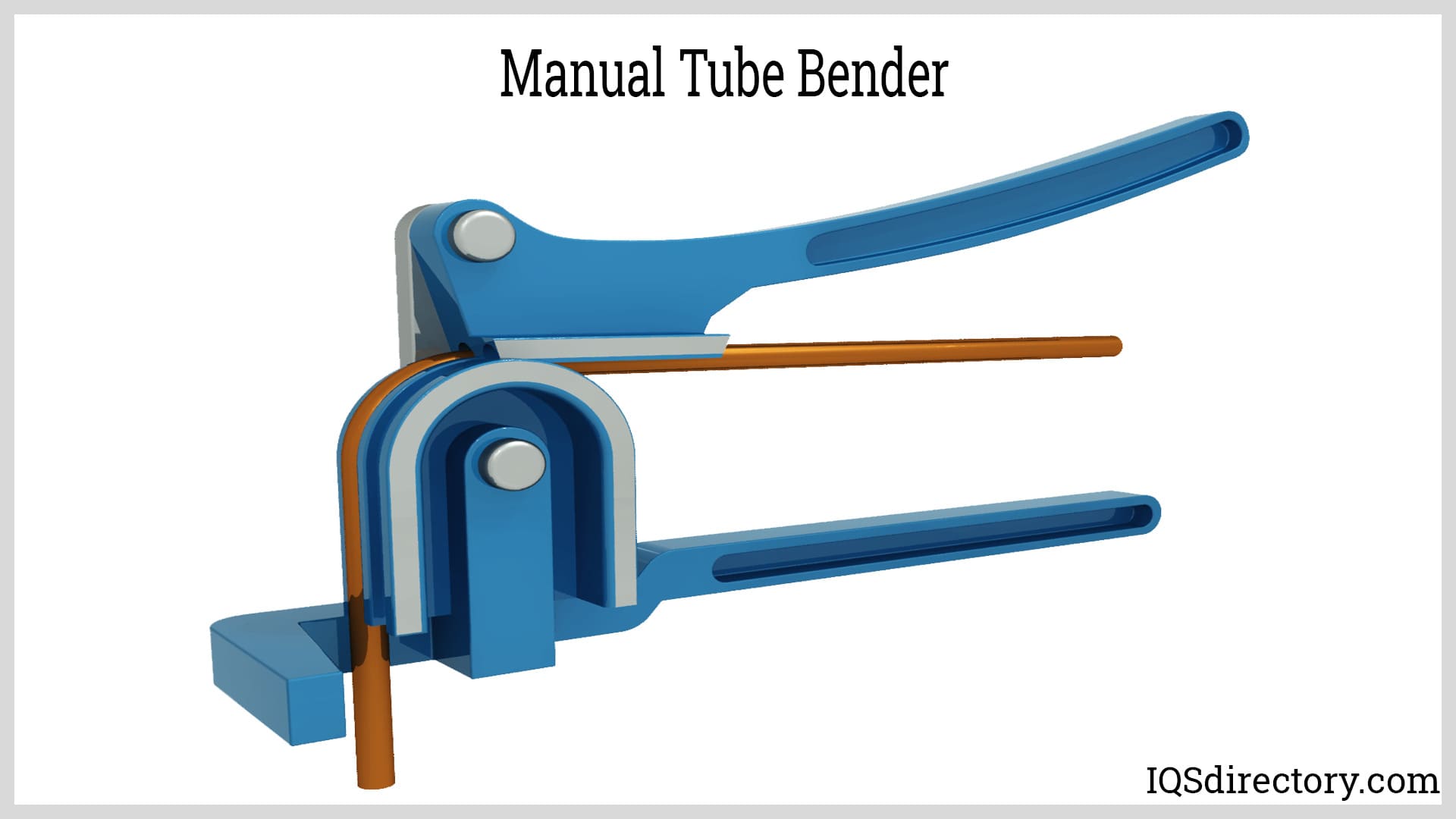

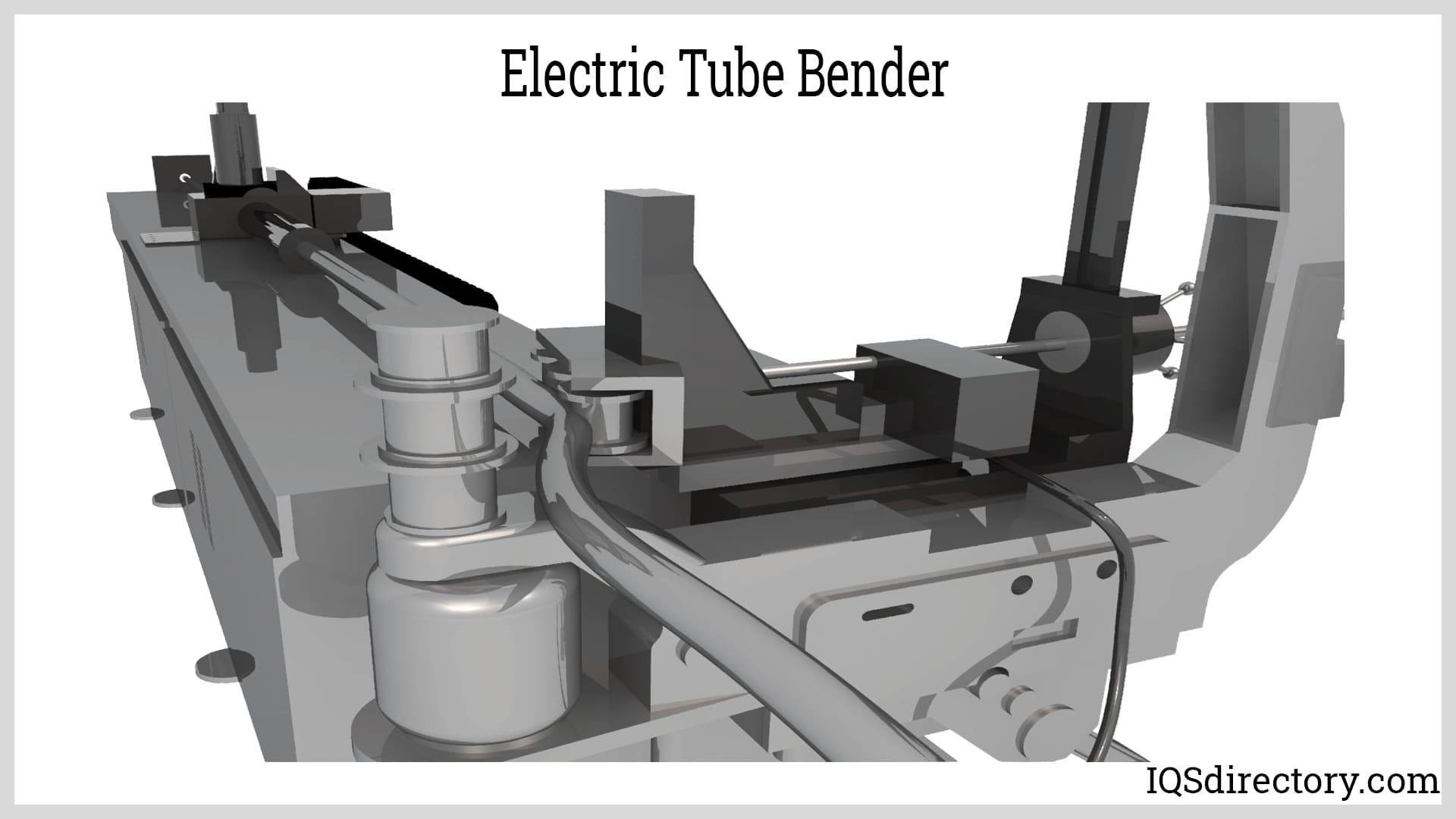

Tube Benders

Manual Tube Bender: Manual tube benders rely on the user's physical strength to bend the tube. Compared to other options, these tube benders are less expensive. These have a limited range of use because they can't bend pipes with thick walls or materials of higher strength.

Electric Tube Bender: These tube benders move the dies and carry out the bending process using an electric servomotor. These are slightly more expensive than manual benders, but they work incredibly well with hard pipes.

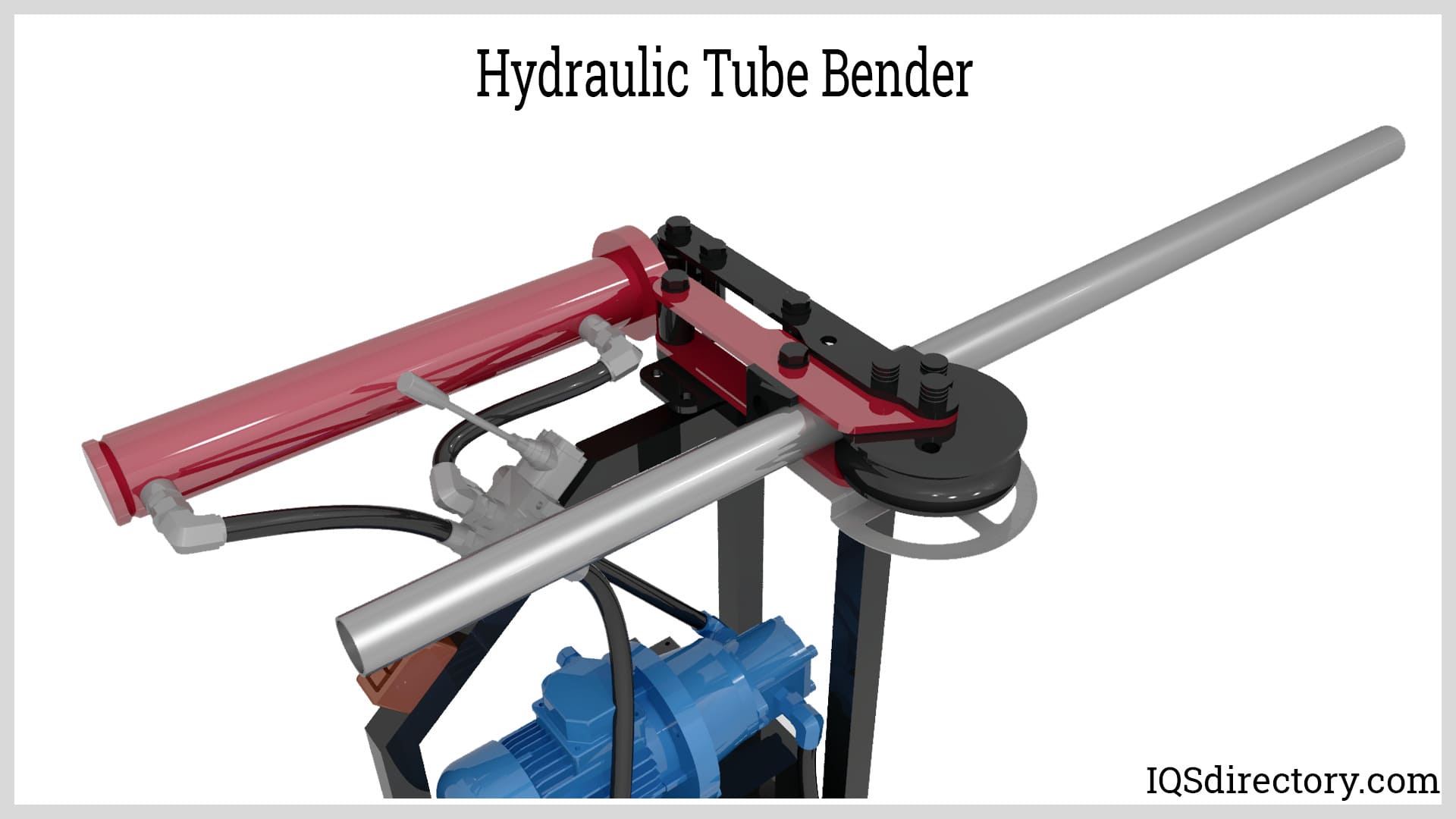

Hydraulic Tube Bender: Hydraulic tubes are based on hydraulic fluid pressure, and these tube benders can easily bend very thick and tough tubes. Hydraulic and electric tube benders are one type that can run with or without electricity.

Benefits Of Tube Bending

- Eliminate risk of leaks

- Eliminate welds, joints, and fixtures

- Minimize flow restrictions

- Lower production costs

- Cleaner and smoother finishes

Choosing the Proper Tube Bending Company

To make sure you have the most beneficial outcome when selecting a tube bending company, it is important to compare at least 5 companies using our list of tube bending companies. Each tube bending company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each tube bending company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple tube bending companies with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services