Founded in 1990, Sharpe Products is an ISO 9001:2015 certified company specializing in industrial and commercial pipe and tube bending, laser cutting, end-forming or other custom fabrication services. In addition, we offer a robust line of architectural handrail fittings and accessories such as brackets, connectors, disks, end-caps, flanges, newel caps and spheres.

Founded in 1959, Tube Bending Technology has its roots in the Apollo space program. With such a legacy, we take quality, performance and customer satisfaction very seriously. Our custom tubing services include tube bending and coiling, end finishing, processing, machining, welding/brazing, helium leak detection and more. At TBI, we live and breathe quality. To show our commitment, we are ISO...

At KMK Metal Fabricators, Inc., we pride ourselves on being industry leaders in tube fabrication, offering a comprehensive range of services tailored to meet the diverse needs of our clients. With years of experience, a commitment to excellence, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our core focus lies in providing...

SCR Precision Tube offers the best customer service in the industry, specializing in prototyping & design of tube, hose & fittings assemblies. Our CNC facility has full tube bending, cutting & swagging capabilities with elbows & straight tubing in steel, aluminum, copper & titanium. Email for a quote!

At TBC Metalworks, we take pride in our expertise in tube fabrication, offering tailored solutions to meet the diverse needs of our clients across various industries. With years of experience, a commitment to quality, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our primary focus is on providing a comprehensive range of tube...

More Tube Cutting Manufacturers

Tubes are used to serve many functions: containment, support, transportation, protection etc.

Tube cutting is used to aid the use of tubes in the agricultural, construction, aerospace, automotive, electrical and medical industries for applications that range from prototypes to large production runs or basic engines and flow systems.

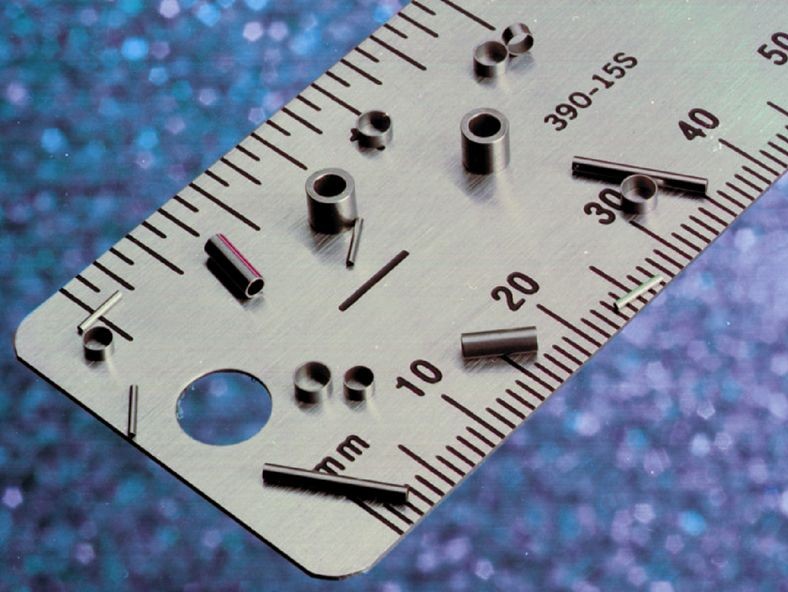

A variety of processes, including both hot and cold working methods can be employed in the process of cutting tubes and piping. Tubes can range greatly in durability, density and hardness, depending on their intended application. In accordance with the hardness of the tube material, its thickness and diameter, and the specifications of the end of the tube, a range of tube cutters can be used. Handheld cutters are often used to trim pipes made from plastics or from softer metals such as aluminum, copper and brass.

Other tools used for cutting are circular saws, horizontal band saws, lathes, lasers and electronically powered blades. Heavy-duty cutting machines are required for larger tubing made of stronger metals such as iron or stainless steel, and in most cases, these cutters will be bench-mounted or attached to a larger piece of machinery. The cutting machine needs to be durable and easy to operate as part of a tube fabricating system.

Most tube cutting is done by the blade making a full rotation around the circumference of the tube and slicing through the wall. Internal cutters are typically abrasive blades or contoured blades which cut a tube from the inside out. For applications requiring a tube to be cut without space for a rotational cutter, a cutter with a hinged handle and blade can be used. As tube cutting can result in surface imperfections along the edge of the cut, extra finishing process may be required such as sanding or polishing to finish the process of cutting.

Automatic deburring machines are available to remove burrs in a method known as shear tube cutting. Cutting can be done at many different stages depending on the application and the configurations of the tubing. Tube bending and pipe bending can be done before tube cutting is done to trim the tube to the exact lengths. Computerized machinery can also be used to ensure the precision of the operation and to direct the electronic system in control of the blade. This will typically result in a better finish than manual cutting although it is not always feasible.

Broaching

Broaching CNC Machining

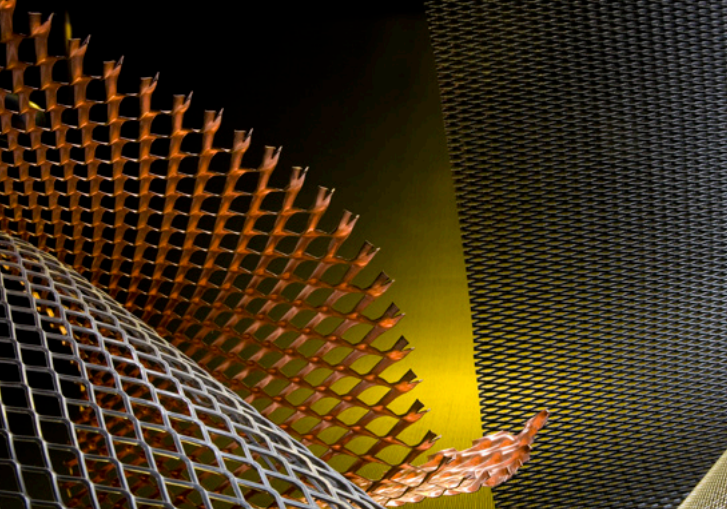

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

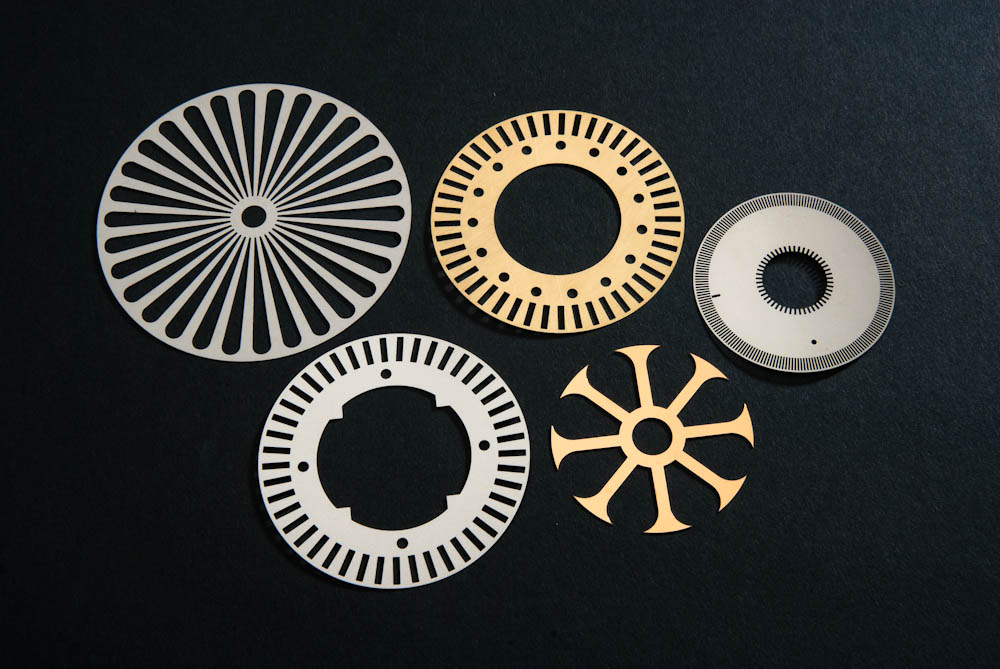

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

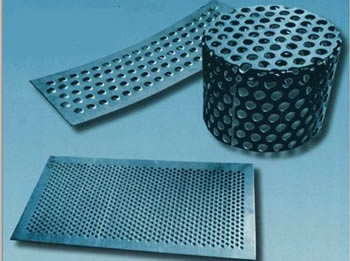

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

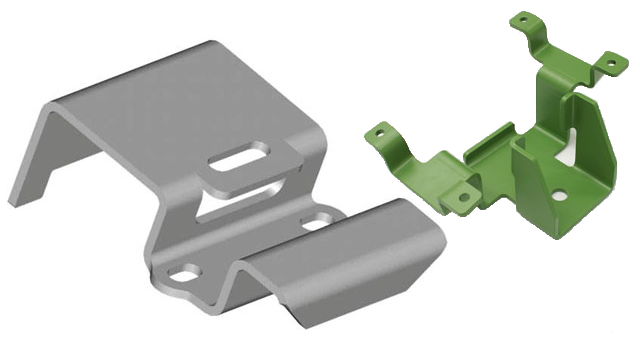

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services