Founded in 1990, Sharpe Products is an ISO 9001:2015 certified company specializing in industrial and commercial pipe and tube bending, laser cutting, end-forming or other custom fabrication services. In addition, we offer a robust line of architectural handrail fittings and accessories such as brackets, connectors, disks, end-caps, flanges, newel caps and spheres.

Founded in 1959, Tube Bending Technology has its roots in the Apollo space program. With such a legacy, we take quality, performance and customer satisfaction very seriously. Our custom tubing services include tube bending and coiling, end finishing, processing, machining, welding/brazing, helium leak detection and more. At TBI, we live and breathe quality. To show our commitment, we are ISO...

At KMK Metal Fabricators, Inc., we pride ourselves on being industry leaders in tube fabrication, offering a comprehensive range of services tailored to meet the diverse needs of our clients. With years of experience, a commitment to excellence, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our core focus lies in providing...

SCR Precision Tube offers the best customer service in the industry, specializing in prototyping & design of tube, hose & fittings assemblies. Our CNC facility has full tube bending, cutting & swagging capabilities with elbows & straight tubing in steel, aluminum, copper & titanium. Email for a quote!

At TBC Metalworks, we take pride in our expertise in tube fabrication, offering tailored solutions to meet the diverse needs of our clients across various industries. With years of experience, a commitment to quality, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our primary focus is on providing a comprehensive range of tube...

More Tube Flaring Manufacturers

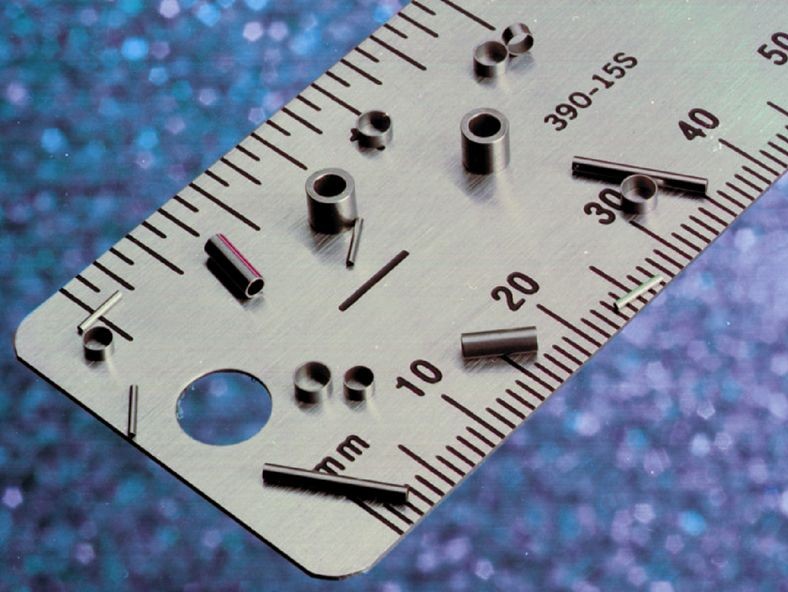

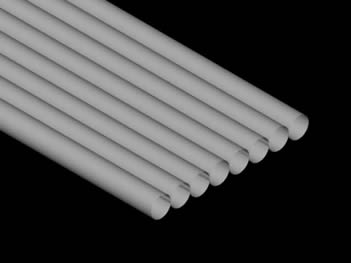

Many industries require the use of pipes and tubing in a flow system and therefore the ability to connect pipes and tubes without leakage is important.

Flaring creates a funnel shape at the end of the tube, which is designed to exactly match the dimensions of what the tube is being fitted against in order to create a tight seal. During the installation of the tube, the flare is matched exactly with a threaded fitting. The inside of the tube's flare fits against the cone-shaped end of the fitting.A flare nut then screws the fitting together and brings the flare flush against the joining component. This creates a tight seal between the two pieces and eliminates the need for a gasket between the tube and fitting.

Flaring is a similar process to tube swaging in that a seal is created between two previously unattached tubes and tube components. After joining, liquids and gases are then able to pass through the tube system securely. For tubes that are subject to more wear and tear and are used in rougher environments, double lap flaring can be implemented to make the tube end stronger and give the inner surface of the flare a slightly thicker diameter.

A common flaring tool is used to make both single and double flares, and the most used angle for both is 45°. A die block with holes in it is used for the process. The holes allow different diameters of tubing to be handled correctly. A clamp then locks the ends of the tube into the holes, and makes a clean cut at the end in order for the most precise flaring.

A yoke with a cone-shaped compressor is attached to the die block and fits over the top of the clamped tube end. A t-shaped handle is used to move the compressor screw into the tube under great pressure, forcing a single flare at the end of the tube. The size of the flare depends on how far the end of the tube extends beyond the clamp of the die block.

To create a double lap flare, the process is the same; however the tube is turned slightly by adapters to create the double lap. The process of flaring can be time consuming as the resulting flare has to be big enough to fit snugly against the fitting, but small enough to fit the flare nut threads accurately.

Broaching

Broaching CNC Machining

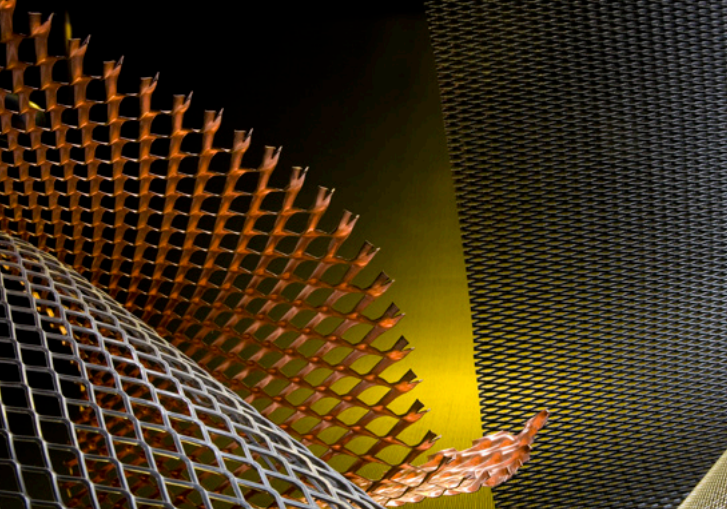

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

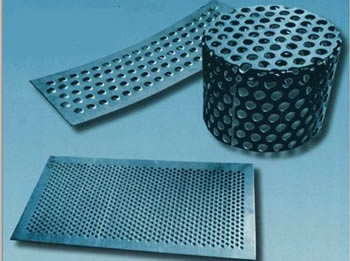

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

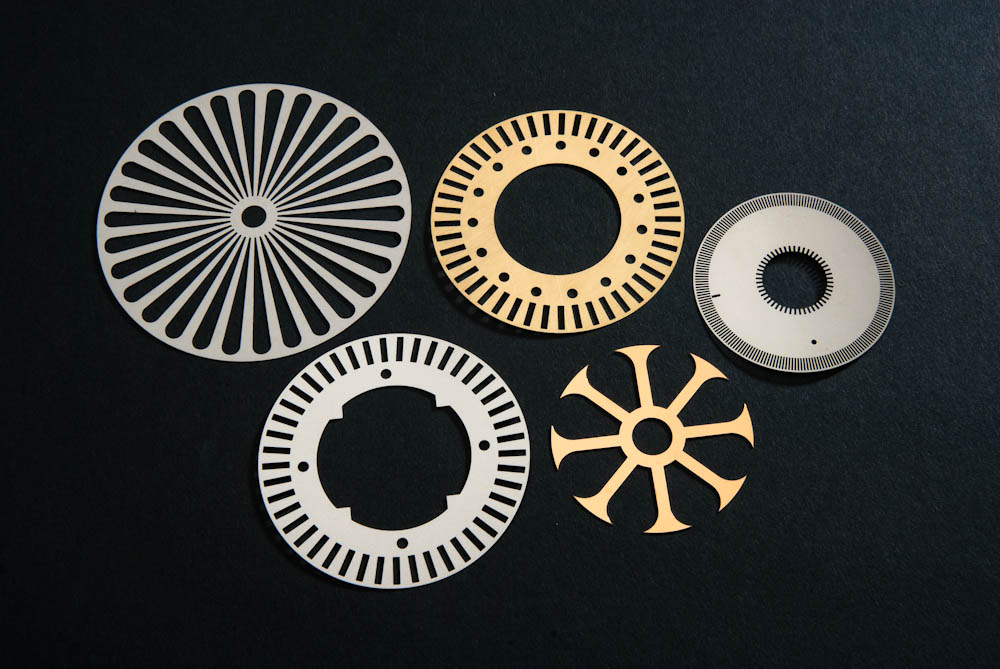

Screw Machine Products Metal Stampings

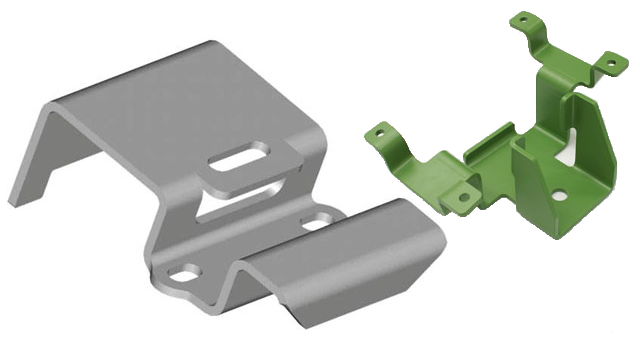

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services