Founded in 1990, Sharpe Products is an ISO 9001:2015 certified company specializing in industrial and commercial pipe and tube bending, laser cutting, end-forming or other custom fabrication services. In addition, we offer a robust line of architectural handrail fittings and accessories such as brackets, connectors, disks, end-caps, flanges, newel caps and spheres.

Founded in 1959, Tube Bending Technology has its roots in the Apollo space program. With such a legacy, we take quality, performance and customer satisfaction very seriously. Our custom tubing services include tube bending and coiling, end finishing, processing, machining, welding/brazing, helium leak detection and more. At TBI, we live and breathe quality. To show our commitment, we are ISO...

At KMK Metal Fabricators, Inc., we pride ourselves on being industry leaders in tube fabrication, offering a comprehensive range of services tailored to meet the diverse needs of our clients. With years of experience, a commitment to excellence, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our core focus lies in providing...

SCR Precision Tube offers the best customer service in the industry, specializing in prototyping & design of tube, hose & fittings assemblies. Our CNC facility has full tube bending, cutting & swagging capabilities with elbows & straight tubing in steel, aluminum, copper & titanium. Email for a quote!

At TBC Metalworks, we take pride in our expertise in tube fabrication, offering tailored solutions to meet the diverse needs of our clients across various industries. With years of experience, a commitment to quality, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our primary focus is on providing a comprehensive range of tube...

More Custom Tubing Manufacturers

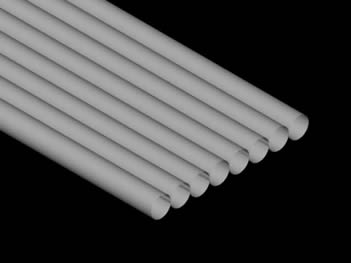

Custom tubing is a specialized form of tube fabrication, offering tailored solutions for a wide range of industries. Its ability to meet specific requirements and achieve precise fit and form has made it indispensable in various applications.

Components Common to Tubing

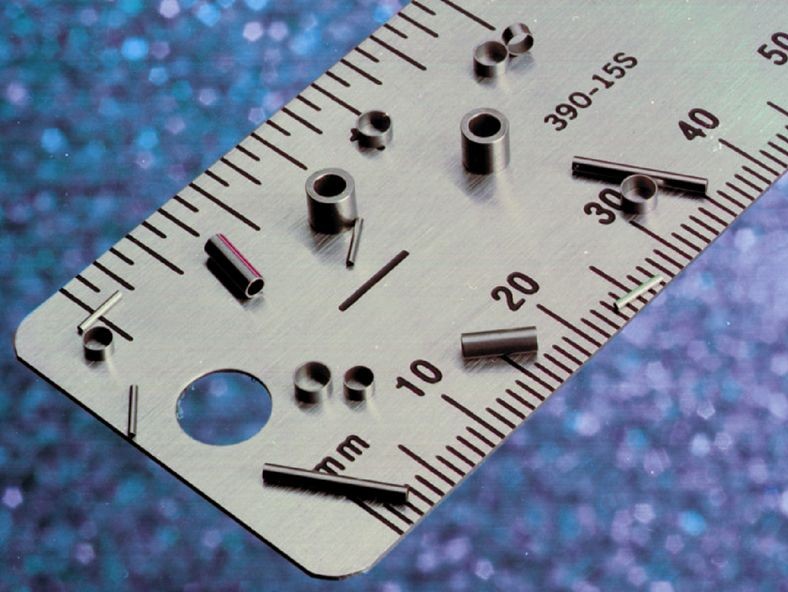

In the realm of custom tubing, the familiar components of outer diameter (OD), inner diameter (ID), wall thickness, and length take on a new level of customization. Unlike standard tubing, custom tubing allows for variations in OD and ID specifications, enabling a perfect match for specific needs. Wall thickness can also be adjusted to accommodate different levels of strength and durability, while length can be customized to suit the requirements of the application. Additionally, the choice of material composition can be tailored to meet specific demands.

Components Specific to Various Forms of Custom Tubing

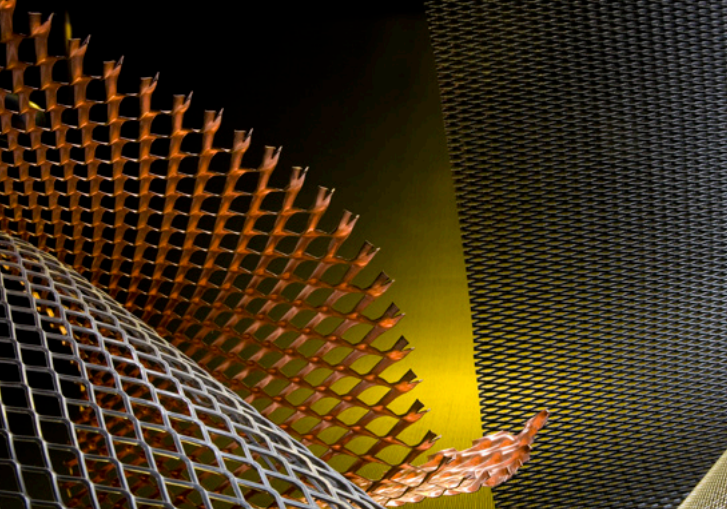

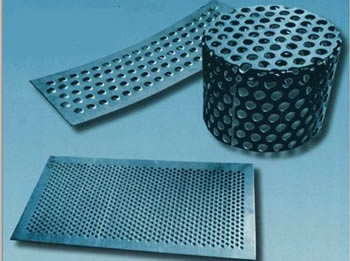

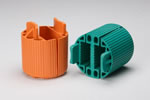

Custom tubing comes in various forms, each tailored to specific applications and created through specialized processes. Coiled tubing, commonly used in the oil and gas industry for well intervention and production, is manufactured by coiling long lengths of tubing into a compact form. Square and rectangular tubing, widely utilized in construction for support structures, are typically produced by cutting and shaping flat sheets of metal or other materials into the desired shape and then welding the edges together. Meanwhile, finned tubing, employed in heat exchangers for improved heat transfer, is created by attaching fins to the outer surface of the tubing using techniques like extrusion or brazing. Furthermore, perforated tubing, used in filtration systems, is made by drilling or punching holes at regular intervals along the length of the tube. Finally, shaped tubing, such as oval or D-shaped profiles often found in automotive applications, is manufactured using specialized forming processes like roll forming or hydroforming, where the tubing is shaped to the desired contour.

Materials Used for Custom Tubing

Custom tubing caters to diverse material needs based on specific applications. Stainless steel is highly favored in the medical industry, finding use in surgical instruments and implants. Aluminum, known for its lightweight and corrosion-resistant properties, is a preferred choice in the aerospace industry for aircraft frames and components. Copper tubing is prevalent in HVAC systems, particularly for refrigerant lines. Plastic materials like PVC and polyethylene are widely utilized in water distribution systems, serving as durable plumbing pipes.

Processes and Equipment for Creating Custom Tubing

Creating custom tubing involves a range of processes and equipment. Tube cutting and shaping techniques allow precise customization for industrial machinery, such as conveyor systems. Tube bending, on the other hand, is a vital process in the automotive industry, forming exhaust systems with intricate shapes. Tube welding, meanwhile, plays a significant role in food processing, ensuring sanitary piping systems. Additionally, tube swaging finds application in the electronics sector, facilitating efficient cable management systems.

Considerations Regarding Custom Tubing

While custom tubing offers tailored solutions, there are a few considerations to keep in mind. To start, cost can be higher compared to standard tubing due to the specialized nature of manufacturing. Lead times may also be longer, as customization requires additional processing steps. Additionally, flexibility may also be limited when working with complex shapes or materials with specific properties.

Efforts to Combat These Considerations

Custom tubing fabricators are actively addressing these concerns through advanced manufacturing techniques, embracing automation and robotics to streamline production processes. These efforts aim to reduce costs, optimize lead times, and expand design possibilities, ensuring a more accessible and efficient custom tubing experience.

Benefits of Custom Tubing

Custom tubing offers a host of benefits that make it a preferred choice in various industries. With precise fit and form, custom tubing ensures a perfect match for specific applications, minimizing leaks and improving system efficiency. Its ability to enhance performance and efficiency through optimized dimensions and material selection is advantageous in heat exchangers, automotive fluid transfer systems, and more. The versatility and adaptability of custom tubing allow for compatibility with existing systems and integration into a wide range of applications. The vast material selection available allows for tubing tailored to specific requirements and enhances durability and performance. Additionally, cost-effectiveness is achieved through minimized waste and optimized production processes.

Applications of Custom Tubing

Custom tubing finds a multitude of applications across various industries, each tailored to meet specific needs and requirements. In the oil and gas industry, custom tubing, particularly coiled tubing, plays a vital role in well intervention and production processes. It allows for efficient deployment and retrieval of tools and equipment, contributing to enhanced oil recovery and well maintenance. In construction, meanwhile, custom square and rectangular tubing serve as the backbone of support structures and frameworks. These sturdy components provide structural integrity and stability for buildings, bridges, and other infrastructure projects. The automotive industry relies on custom tubing for fluid transfer systems, ensuring reliable and leak-free transportation of liquids and gasses within vehicles. Additionally, in the realm of heat exchangers, finned tubing is widely employed to optimize heat transfer in applications such as HVAC systems, refrigeration units, and air conditioning systems.

The medical field extensively utilizes custom tubing for surgical implants and devices. Materials like stainless steel are commonly employed to manufacture surgical instruments, ensuring precision and durability during procedures. In the aerospace industry, additionally, custom tubing, often made from lightweight and corrosion-resistant materials like aluminum, finds application in aircraft frames and components. Its high strength-to-weight ratio contributes to fuel efficiency and structural integrity. Furthermore, HVAC systems rely on custom copper tubing for refrigerant lines, enabling the efficient transfer of heat and maintaining ideal temperature control. And in water distribution systems, custom plastic tubing, such as PVC and polyethylene, provides durable and corrosion-resistant plumbing pipes, ensuring the safe and reliable transport of water.

The applications of custom tubing don’t end there as industrial machinery often requires custom tubing for specialized purposes. Tube cutting and shaping techniques allow for the creation of precise conveyor systems, facilitating efficient material handling and automation. In the food processing industry, tube welding ensures the integrity and cleanliness of sanitary piping systems, preventing contamination and ensuring food safety. Custom tube bending is also essential in the electronics sector, particularly for cable management systems. It allows for the creation of optimized wire harnesses, enabling organized and efficient routing of electrical cables and connections.

These various applications demonstrate the versatility and adaptability of custom tubing, meeting the unique demands of each industry. Through customization of dimensions, materials, and fabrication techniques, custom tubing offers tailored solutions that contribute to improved performance, reliability, and overall system efficiency in diverse sectors.

Choosing the Right Custom Tubing Company

To ensure you have the most positive outcome when selecting a custom tubing company, it is important to compare several businesses using our directory of custom tubing business. Each custom tubing company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or to request a quote. Review each custom tubing business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple custom tubing businesses with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

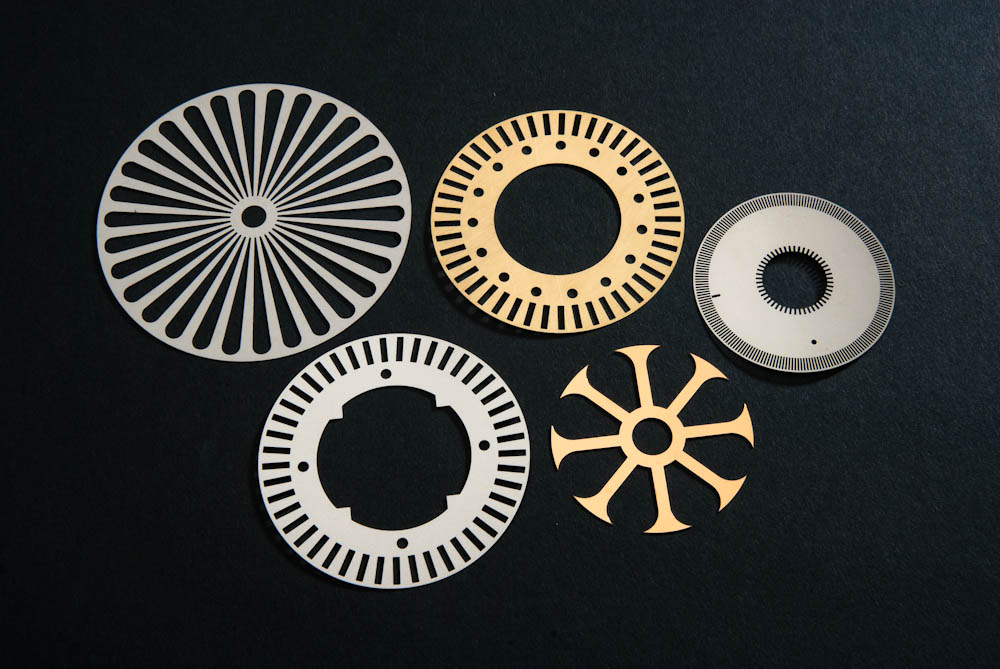

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

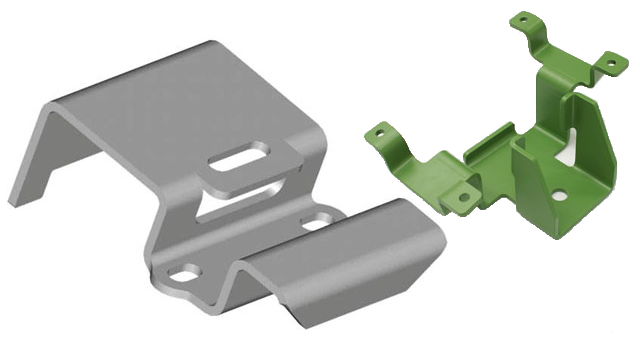

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services