Founded in 1990, Sharpe Products is an ISO 9001:2015 certified company specializing in industrial and commercial pipe and tube bending, laser cutting, end-forming or other custom fabrication services. In addition, we offer a robust line of architectural handrail fittings and accessories such as brackets, connectors, disks, end-caps, flanges, newel caps and spheres.

Founded in 1959, Tube Bending Technology has its roots in the Apollo space program. With such a legacy, we take quality, performance and customer satisfaction very seriously. Our custom tubing services include tube bending and coiling, end finishing, processing, machining, welding/brazing, helium leak detection and more. At TBI, we live and breathe quality. To show our commitment, we are ISO...

At KMK Metal Fabricators, Inc., we pride ourselves on being industry leaders in tube fabrication, offering a comprehensive range of services tailored to meet the diverse needs of our clients. With years of experience, a commitment to excellence, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our core focus lies in providing...

SCR Precision Tube offers the best customer service in the industry, specializing in prototyping & design of tube, hose & fittings assemblies. Our CNC facility has full tube bending, cutting & swagging capabilities with elbows & straight tubing in steel, aluminum, copper & titanium. Email for a quote!

At TBC Metalworks, we take pride in our expertise in tube fabrication, offering tailored solutions to meet the diverse needs of our clients across various industries. With years of experience, a commitment to quality, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our primary focus is on providing a comprehensive range of tube...

More Pipe Fabrication Manufacturers

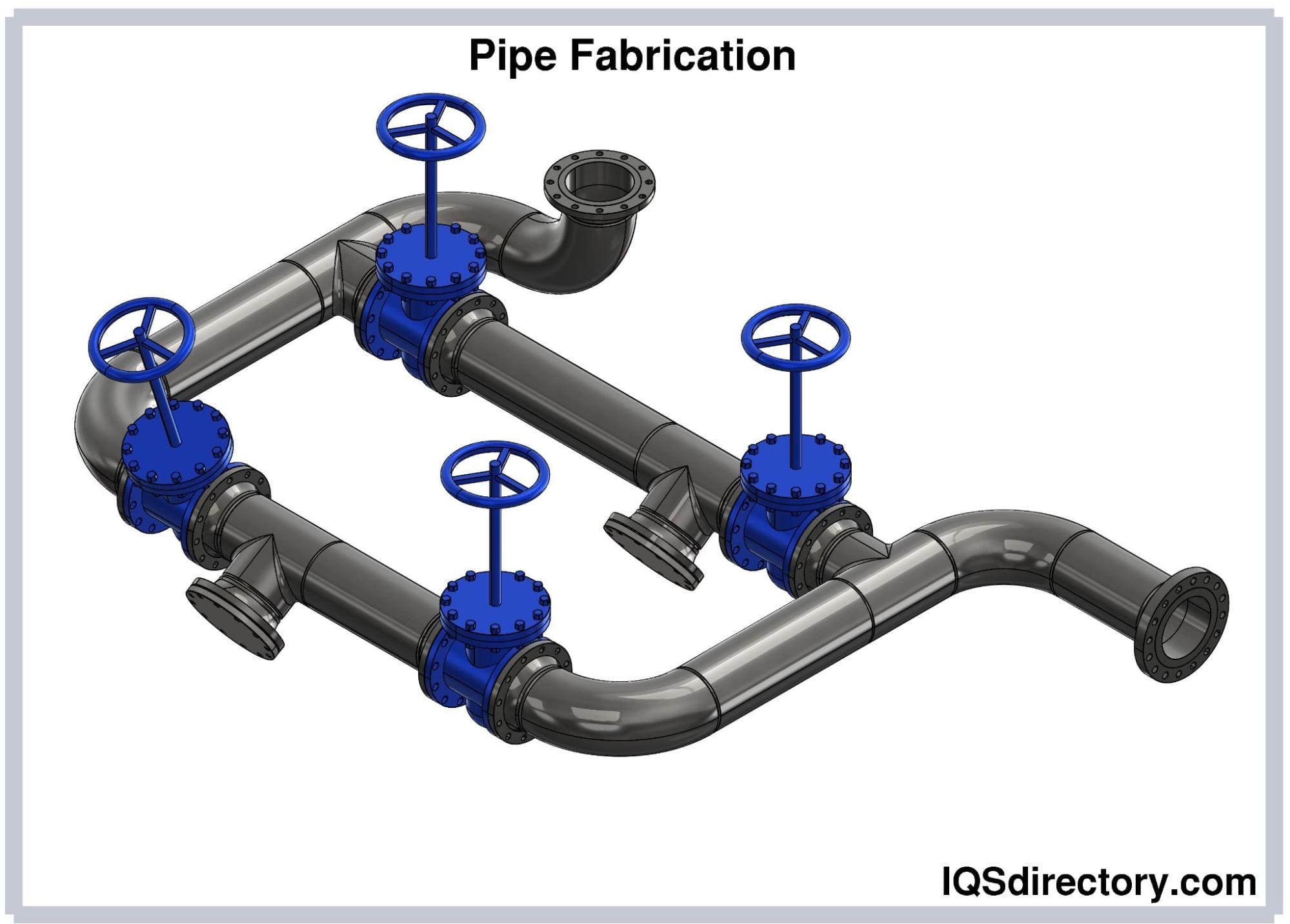

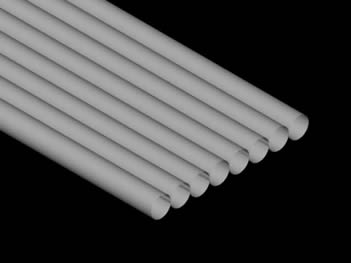

Pipe fabrication is manufacturing straight pipes for specific applications with additions like elbows, tees, reduced fittings, and flanges. These pipe components are important to provide a simple or complex piping system. Manufacturers can fabricate predesigned piping systems for irrigation, fire protection, and plumbing. Piping systems are custom-made to accommodate specific environments.

Pipe fabrication is a complex process requiring complete precision to transport materials safely. Pipe fabrication involves multiple processes, including cutting, welding, bevelling, and bending procedures. The quality of pipe fabrication, installation, and layout is critical; it requires proper planning and execution to avoid accidents.

Selecting the Right Material for Pipe Fabrication

Manufacturers and clients are responsible for considering certain factors when selecting pipe materials. Planning should accommodate specific fluid types, internal temperature/pressure, and the environment where the pipe installation will occur. Planning around these factors will help manufacturers choose the best pipe material.

Certain materials are used for manufacturing pipes. Some of these are discussed below:

Standard Steel for Pipe Fabrication

Steel is the most commonly used pipe fabrication material because it’s affordable, long-lasting, resistant, and deformable. Steel will withstand vibrations, impacts, high temperatures, and pressures. Standard steel is easy to bend and cut. To avoid corrosion, the steel should be galvanized during the pipe fabrication process.

P91 Steel for Pipe Fabrication

P91 is an alloy with chromium, molybdenum, and manganese. These additional elements increase P91’s creep resistance, hardness, and corrosion resistance. Excessive heating can damage P91 steel, so it’s advised to use cold machining when fabricating this material. P91 was mostly used in conventional and nuclear thermal power plants.

Duplex Steel in Pipe Fabrication

Duplex steel is a combination of chromium and nickel. It has impressive tensile strength and corrosion resistance making it ideal for saline environments. Pipes used for petroleum, oil, and gas industries are often made of duplex steel. Duplex steel can be difficult to machine; it requires strong machinery with clamps to be fabricated.

Stainless Steel in Pipe Fabrication

Stainless steel is composed of iron, carbon with added chromium, and other elements such as nickel, molybdenum, and titanium. Stainless steel is also corrosion-resistant and functional at high temperatures and pressure. Stainless steel pipes transport corrosive fluids in pharmaceuticals, chemical, and petroleum industries.

Superalloys and Titanium

Most super-alloys are nickel-based alloys with great heat and corrosion resistance. However, they may be more expensive than other materials. These are used in the aeronautical and chemical industries. Titanium is an expensive metal, but it's used in aeronautics because of its lightweight nature.

Aluminum Pipes

Aluminum is a softer, malleable metal that is easy to machine and assemble. Aluminum also provides corrosion resistance at an affordable price. Aluminum pipes are widely used in the aerospace, construction, and transport industries.

Types of Pipe Fabrication

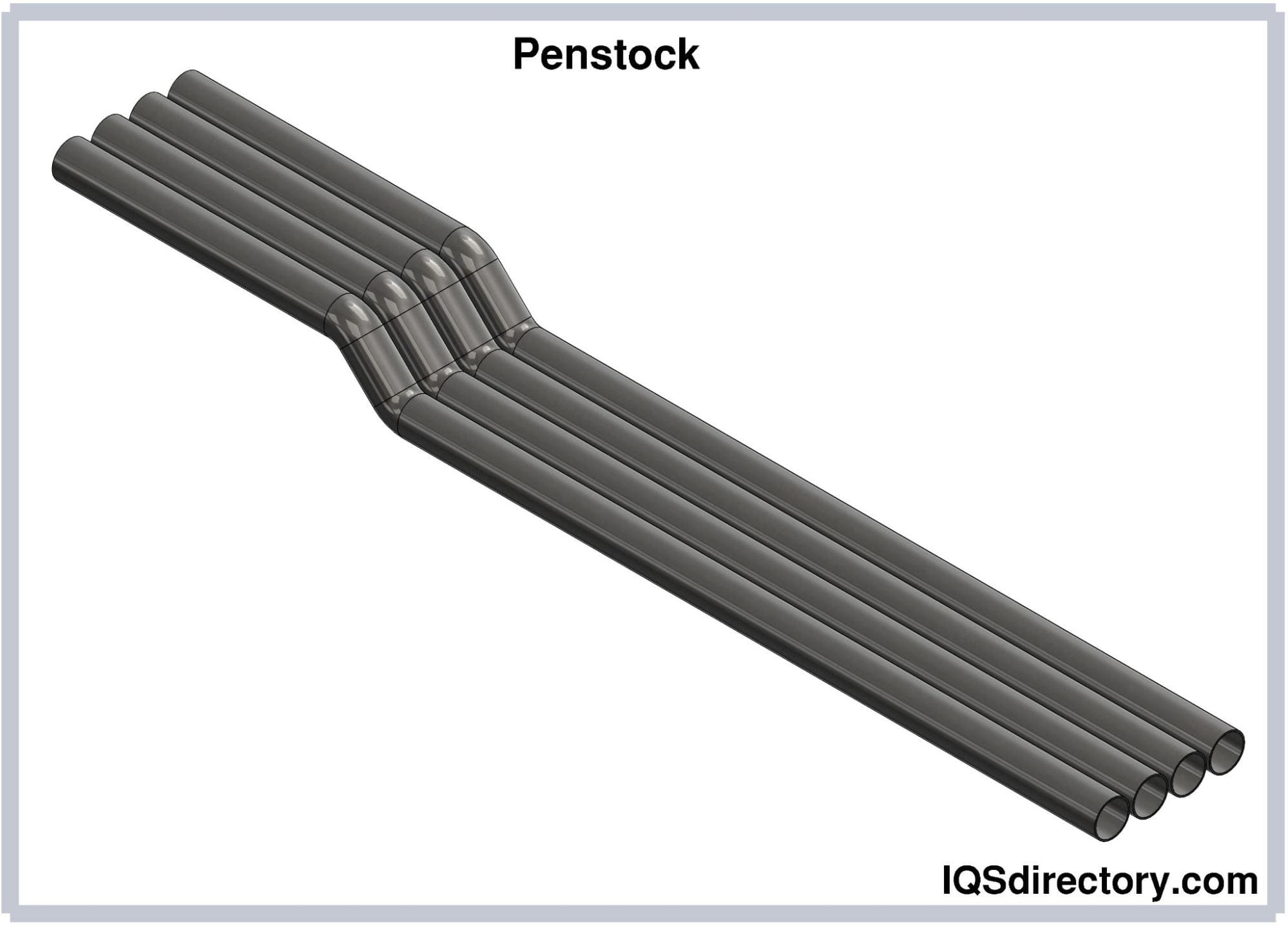

There are three types of pipe fabrication, each serving a different function. Firstly, penstock piping is used to transport municipal water.

Casing piping is used to provide structural support or project wiring. There are two types of casing, vertical and horizontal. The vertical casing is concrete filled to give structural support whereas the horizontal casing is used to protect the underground utility lines.

Piling is a third type of piping primarily used to provide stability to the building’s foundation.

The Pipe Fabrication Process

The material is marked and cut according to the client's requests. Marking is preparation for cutting. The pipes are tagged with numbers through die stamping or printing processes. Next, the material is cut for the pipes. Different cutting methods are used for different types of material used for piping.

The ends of the pipes are prepared through bevelling. The ends are usually fabricated according to specifications. Welding pipe ends should be done with great care so that the seams do not settle in an odd manner. A metal paint marker is used to write details on the pipe, such as the pipeline number or component number. This marker is also used to write the spool number of the pipe. Fabricated pipe spools are heat treated at the site according to the application.

The spools are then inspected using quality guidelines. Defected spools are tagged yellow or black and sent back for repair. Once field inspection is done, all the reports are documented in the approved format. The ready spools are covered with plywood blinds, and the edges are covered with caps to protect the spools.

Applications of Pipes

Pipes are used in almost every industry, such as plumbing, irrigation, gas & oil, water transport, and construction. Therefore, fabricating pipes can vary according to the custom application.

Choosing the Correct Pipe Fabrication Company

To make sure you have the most beneficial outcome when selecting a pipe fabrication company, it is important to compare at least 4 companies using our pipe fabrication directory. Each pipe fabrication company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each pipe fabrication company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple pipe fabrication companies with the same message.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

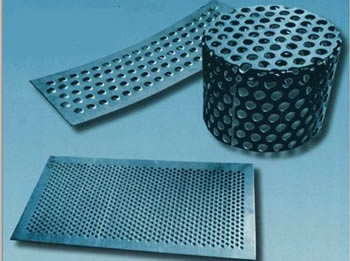

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

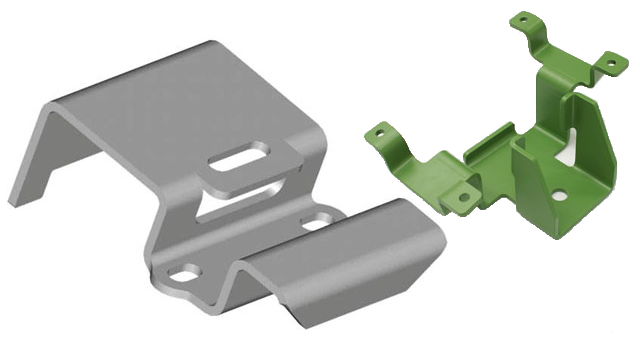

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services