Founded in 1990, Sharpe Products is an ISO 9001:2015 certified company specializing in industrial and commercial pipe and tube bending, laser cutting, end-forming or other custom fabrication services. In addition, we offer a robust line of architectural handrail fittings and accessories such as brackets, connectors, disks, end-caps, flanges, newel caps and spheres.

Founded in 1959, Tube Bending Technology has its roots in the Apollo space program. With such a legacy, we take quality, performance and customer satisfaction very seriously. Our custom tubing services include tube bending and coiling, end finishing, processing, machining, welding/brazing, helium leak detection and more. At TBI, we live and breathe quality. To show our commitment, we are ISO...

At KMK Metal Fabricators, Inc., we pride ourselves on being industry leaders in tube fabrication, offering a comprehensive range of services tailored to meet the diverse needs of our clients. With years of experience, a commitment to excellence, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our core focus lies in providing...

SCR Precision Tube offers the best customer service in the industry, specializing in prototyping & design of tube, hose & fittings assemblies. Our CNC facility has full tube bending, cutting & swagging capabilities with elbows & straight tubing in steel, aluminum, copper & titanium. Email for a quote!

At TBC Metalworks, we take pride in our expertise in tube fabrication, offering tailored solutions to meet the diverse needs of our clients across various industries. With years of experience, a commitment to quality, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our primary focus is on providing a comprehensive range of tube...

More Tube Rolling Manufacturers

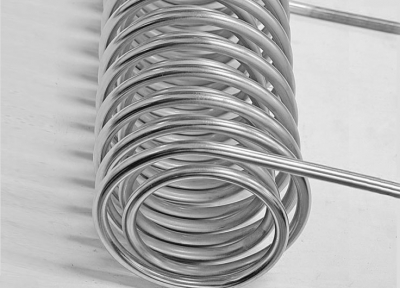

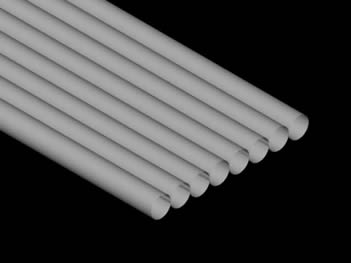

As one of the most widely used tube forming processes, tube rolling allows for high production rates while also providing enhanced strength-to-weight properties.

Some benefits of tube rolling include high part-to-part consistency and good surface finish. Able to produce a broad range of part shapes, such as cylindrical, oval, rectangular, conical and square, tube rolling is used in diverse industries and products including: sports and recreation, for fishing rods, golf shafts, tennis racquets and ski poles; electronics, for antennas and other consumer applications; industrial manufacturing, for heating elements and machine components; and marine and naval defense, for launcher tubes, telescopes and masts.

Tube rolling is often used in custom tube fabricating, since it offers the ability to place fibers either along or around the part with knowledge of the end application. Able to be performed using various materials such as stainless steel, aluminum, titanium, magnesium and brass, tube rolling can fabricate both large and small diameter tubes with low tooling costs due to the use of affordable and durable mandrels, and the versatility of tube cutting.

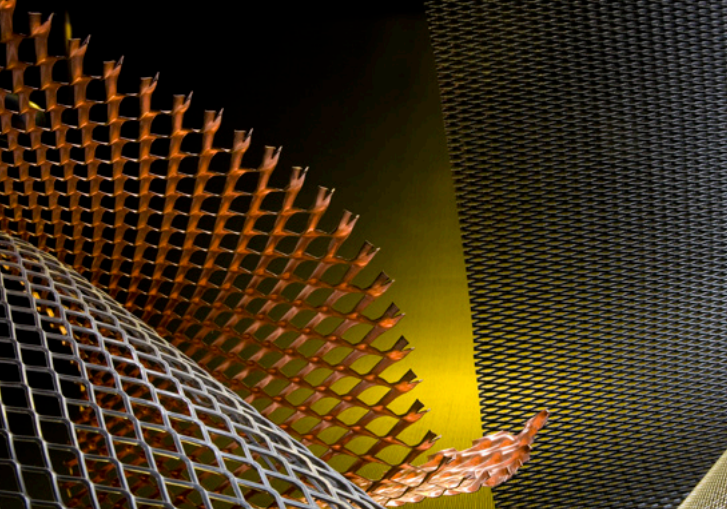

There are many different tube rolling techniques, which are most commonly undertaken using a tube rolling mill. A tube rolling mill can either refer to a factory or a machine; however, in either technique, the method typically remains the same. To begin the process, patterns, or flags, are cut out from materials such as epoxy pre-impregnated carbon, aramid cloth or glass, and then rolled around a mandrel, which is typically made from steel or some other type of metal alloy.

It is essential that a very tight roll is achieved, so that air is not trapped and the fiber is properly aligned. Before the tube can be heat cured, it must be pressure-wrapped with heat-shrinkable plastic film or sleeve. Referred to as debaulking, the wrapping increases the compaction of the part. Now able to be heat-cured, the material-wrapped mandrel is placed within an air-circulated oven or furnace at high temperatures.

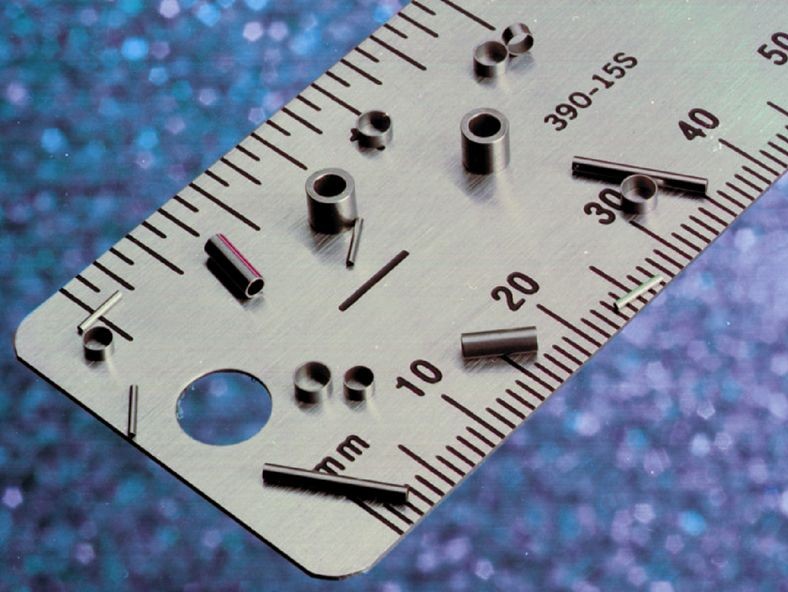

During heat curing, the outer wrapping functions to squeeze air out of the ends of the wrapped material through shrinkage. When the heat curing is finished, the mandrel can be removed, creating a hollow, tubular part with very thin walls. Typical rolled tube diameters range from .76 - 609 mm (.030 - 24 in.), and can reach maximum lengths of about 7.3 m (24 ft.).

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

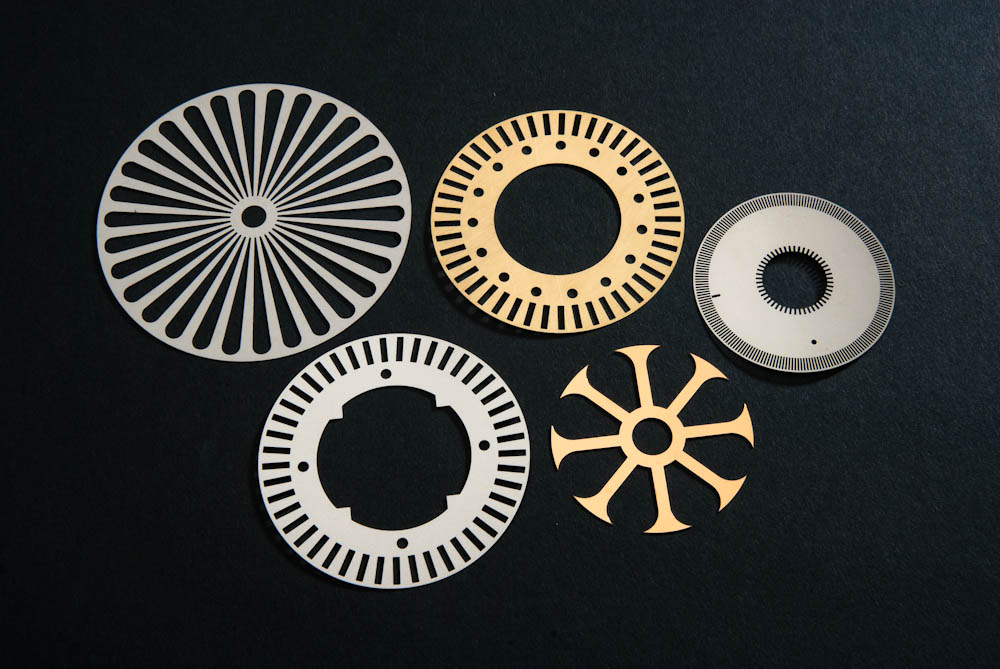

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

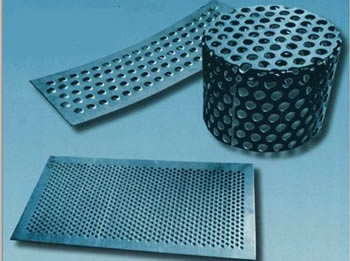

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

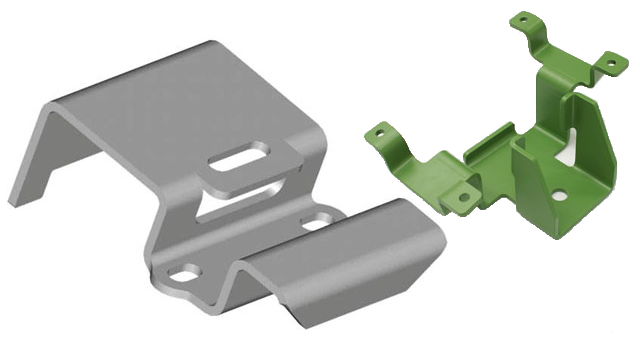

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services