Founded in 1990, Sharpe Products is an ISO 9001:2015 certified company specializing in industrial and commercial pipe and tube bending, laser cutting, end-forming or other custom fabrication services. In addition, we offer a robust line of architectural handrail fittings and accessories such as brackets, connectors, disks, end-caps, flanges, newel caps and spheres.

Founded in 1959, Tube Bending Technology has its roots in the Apollo space program. With such a legacy, we take quality, performance and customer satisfaction very seriously. Our custom tubing services include tube bending and coiling, end finishing, processing, machining, welding/brazing, helium leak detection and more. At TBI, we live and breathe quality. To show our commitment, we are ISO...

At KMK Metal Fabricators, Inc., we pride ourselves on being industry leaders in tube fabrication, offering a comprehensive range of services tailored to meet the diverse needs of our clients. With years of experience, a commitment to excellence, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our core focus lies in providing...

SCR Precision Tube offers the best customer service in the industry, specializing in prototyping & design of tube, hose & fittings assemblies. Our CNC facility has full tube bending, cutting & swagging capabilities with elbows & straight tubing in steel, aluminum, copper & titanium. Email for a quote!

At TBC Metalworks, we take pride in our expertise in tube fabrication, offering tailored solutions to meet the diverse needs of our clients across various industries. With years of experience, a commitment to quality, and a customer-centric approach, we have established ourselves as a trusted partner in the fabrication industry. Our primary focus is on providing a comprehensive range of tube...

More Mandrel Bending Manufacturers

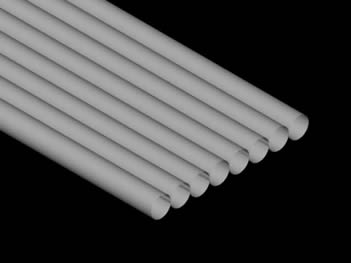

In this process, a mandrel—a metal rod or ball—is inserted into the tube while it is being bent, which creates a more precise bend with no wrinkles or kinks. For some applications, it is acceptable to have a wrinkled tube; particularly when the tube just has to function and quality is not a factor.

The process of mandrel bending provides a high quality tube because the amount of flow is improved, making the inside diameter of the tube consistent throughout, even at the bend; something that is not possible to do without using a mandrel. Mandrel bending is commonly used in exhaust applications in the automotive industry, pipe applications in the plumbing industry and instrument applications in the musical instrument manufacturing industry because the process improves the look of the bend and also creates a much tighter bend than is possible with empty bending. When the mandrel is inserted into the tube, it has to be strong enough to support the tube so that it won’t be deformed during bending, but also flexible enough to ensure that the tube is still properly bent.

Mandrel bending takes place during the rotary-draw tube-bending process. With rotary-draw bending, a tube’s bend is created by placing the tube around the form of a rotating bend. The tube is attached to the bend form, and as the form moves forward it is designed to bend the tube in the right places, specific to each tube. Mandrel bending occurs during this process by placing a mandrel inside the tube so that as the tube is bent, the mandrel bends with it, which helps keep the tube’s shape from deforming and provides a precise bend, free of kinks.

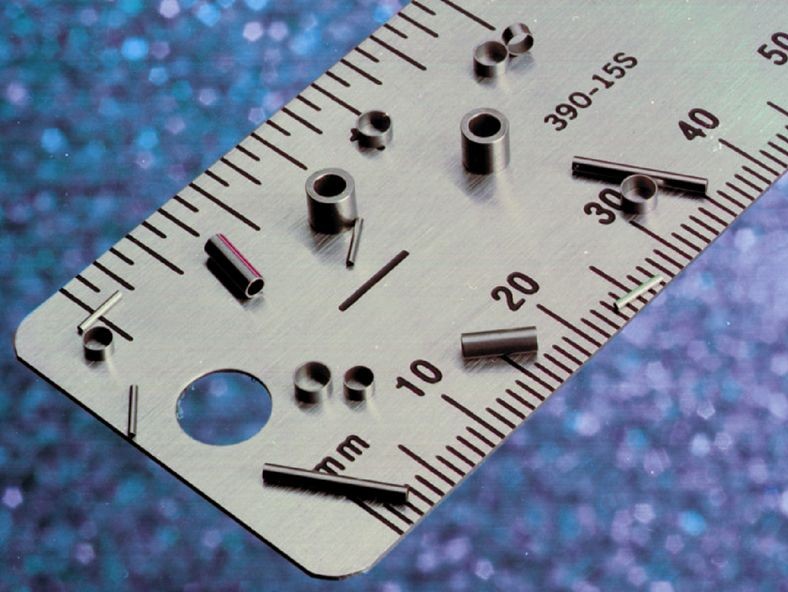

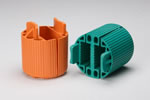

Mandrels are usually made of an aluminum-bronze alloy or steel. The aluminum-bronze type is used to bend harder materials such as stainless steel or titanium, while steel mandrels are typically used to bend softer materials such as copper or aluminum. There are different types of mandrels that meet various bending needs: common types include plug mandrels, form mandrels and ball mandrels. Plug mandrels are solid rods that are inserted into the tube; this type of mandrel is often used on tubes that have thicker walls, a larger radius and are going to be bent normally.

Form mandrels are similar to plug mandrels in that they are also a solid rod, but the tips of these mandrels are formed to fit a tube’s specific radius; essentially, it is a custom mandrel. Ball mandrels consist of ball bearings—which can be linked or unlinked—being inserted into the tube. These mandrels are used when a precise bend is required in a tube.

Broaching

Broaching CNC Machining

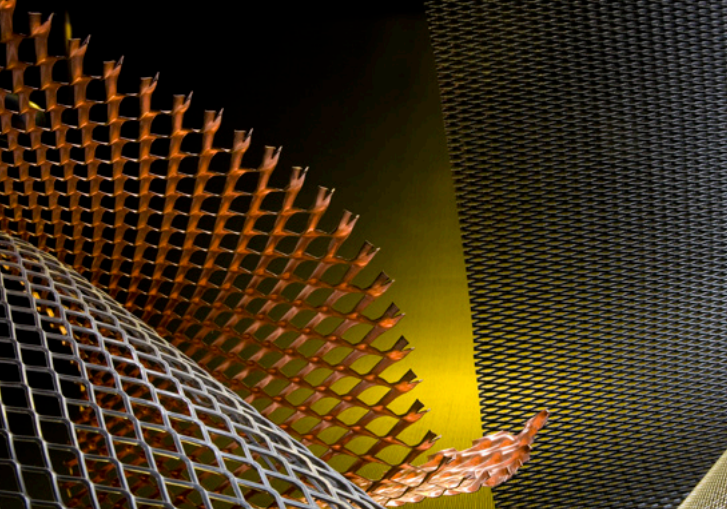

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

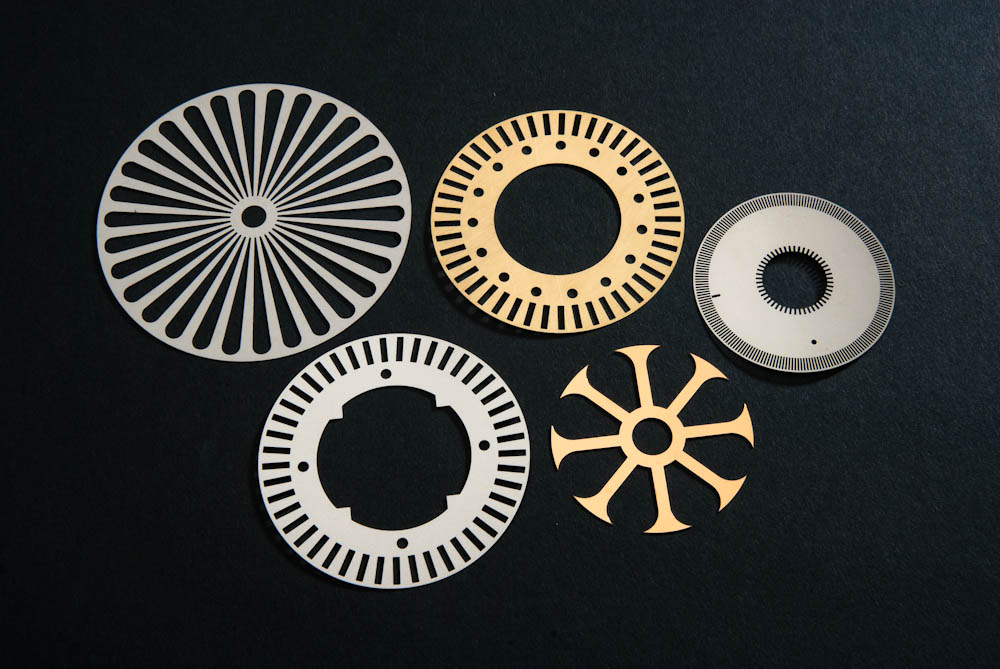

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

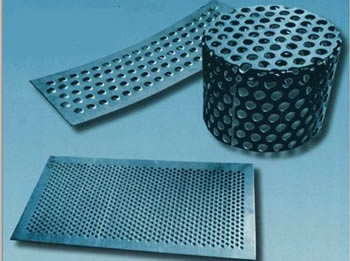

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

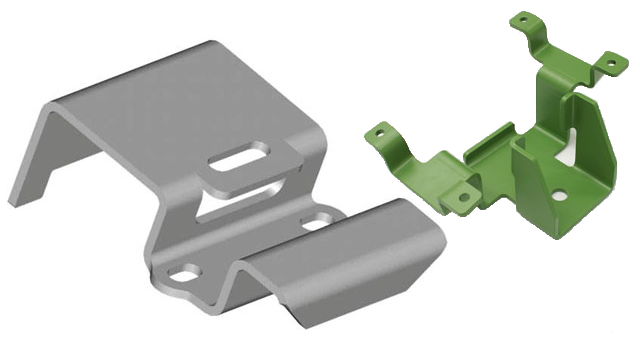

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services